ANSUL

ANSUL® is a global premium brand of Tyco Fire Protection Products. ANSUL special hazard fire protection products are designed and manufactured to strict standards and tested under the scrutiny of national and international independent testing laboratories and approval agencies.

ANSUL fire protection products were introduced to the marketplace in 1939 featuring the first cartridge-operated, dry chemical fire extinguisher. As technology changed and dangerous new hazards emerged, ANSUL product engineers worked hand-in-hand with many industries to protect their people and property from fire. Today, the ANSUL Fire Technology Center and Center of Excellence house one of the most extensive fire research and testing facilities in the world. No other fire protection brand is supported by such extensive broad-based research and test facilities with so many scientists and engineers devoting 100% of their time preparing for the fire protection and safety needs of the future.

ANSUL Vehicle Systems

The LVS Liquid Agent Fire Suppression System utilized in a stand-alone system protects off-road equipment such as above-ground and sub-surface mining equipment, including haul trucks, wheeled loaders, dozers, scoop trams, and shuttle cars. The system is also well suited for other off-road vehicles such as landfill equipment; forestry vehicles; construction equipment; and specialty vehicles such as slag pot carriers, iron/steel slab carriers and tunnel boring equipment. Additional applications include on-road vehicles such as public transportation, waste management, over-the-road trucking, and cargo transport.

| Product Name | Download Link |

|---|---|

| LVS Liquid Agent Fire Suppression System | Datasheet |

The combined performance of the A-101/LVS Twin-Agent Fire Suppression System provides the ultimate protection. While the FORAY dry chemical knocks down flames, the LVS agent cools surrounding areas, minimizing the possibility of reflash. The fire suppression system can be used as a protection of large, off-road type construction and mining equipment such as large excavators/shovels, draglines, haul trucks, and wheeled loaders. The system also protects underground mining equipment and specialty vehicles such as slag pot and/or slab carriers and tunnel boring machines, as well as waste management equipment and forestry vehicles.

| Product Name | Download Link |

|---|---|

| A-101/LVS Twin-Agent Fire Suppression System | Datasheet |

The A-101 Fire Suppression System is an automatic or manual fire suppression system using FORAY dry chemical agent for Class A, B, and C fires. The system is designed for use on large, off-road type construction and mining equipment, underground mining equipment and specialty vehicles.

| Product Name | Download Link |

|---|---|

| A-101 Dry Chemical Fire Suppression System | Datasheet |

Rugged heavy equipment comes with substantial fire safety challenges often requiring an investment in life and property protection. The ANSUL CHECKFIRE 110 Electronic Detection and Actuation System offers cost-effective, single-zone detection and actuation for vehicles used in the extreme environmental and physical conditions of industries like forestry, waste/recycling, aviation and transit. The system is used with an ANSUL A-101 or LVS Vehicle Fire Suppression System for 24-hour protection of equipment.

The CHECKFIRE 110 system provides electrical and/or optional pneumatic input to actuate an ANSUL fire suppression system. When fire is detected, the control module sends an electrical signal to release the gas from an expellant gas cartridge to pressurize and discharge the fire suppression system.

| Product Name | Download Link |

|---|---|

| CHECKFIRE 110 Detection and Actuation System | Datasheet |

The ANSUL CHECKFIRE 210 Supervised Electronic Detection and Actuation System is engineered to stand up to extreme operating environments. This versatile system is designed to provide detection, alarm and fire suppression system actuation for mobile applications like hydraulic excavators, haul trucks, wheeled loaders, dozers and graders.

The CHECKFIRE 210 is used with an ANSUL LVS, A-101, or twin agent vehicle fire suppression system for 24-hour protection of equipment. One of the hallmarks of the CHECKFIRE 210 system is its flexibility in protecting multiple hazard areas. Featuring color-coded, plug-and-play connectors, the system is equipped with two, independent detection circuits configurable for various options including single-zone detection, two-zone detection, cross-zone detection, discharge pressure feedback monitoring or alarm only.

| Product Name | Download Link |

|---|---|

| CHECKFIRE 210 Detection and Actuation System | Datasheet |

The CHECKFIRE MP-N Electronic Detection and Actuation System provides automatic detection and actuation for underground mining equipment. The CHECKFIRE MP-N carries MSHA approval for use in underground mines (Permissible Applications in Explosive Methane/Air Applications).

The rugged control module resists shock and vibration and can be utilized as a self-contained system with its own internal Lithium battery. The CHECKFIRE system is typically used with an ANSUL Vehicle Fire Suppression System for 24-hour protection of equipment including detection, alarm, machine shutdown and fire suppression system actuation.

| Product Name | Download Link |

|---|---|

| CHECKFIRE MP-N Detection and Actuation System | Datasheet |

ANSUL Foam Concentrates

Class B Foam Agents are ideal for suppressing fires involving petroleum-based products, LNG, rubber, and flammable and combustible liquids; such as diesel fuel, crude oil gasoline and ethanol.

ANSULITE® Alcohol-Resistant Aqueous Film-Forming Foam (AR-AFFF) Concentrates produce a foam that is effective on hydrocarbon fuels as well as fuels such as methanol, ethanol and acetone which have appreciable water solubility or miscibility. AR-AFFF exhibits the best cross-functional performance for flame knock-down, burnback resistance, extended vapor suppression, manufacturing and proportioning consistency, and the longest potential shelf life.

| Product Name | Download Link |

|---|---|

| Class B Polar Solvents (AR-AFFF) | Datasheet |

Class B Foam Concentrates are ideal for suppressing fires involving petroleum-based products, LNG, rubber, and flammable and combustible liquids; such as diesel fuel, crude oil gasoline and ethanol.

ANSULITE® Aqueous Film-Forming Foam (AFFF) Concentrates can be applied through a wide variety of delivery systems which provides extreme versatility. The foam is an ideal fire suppression choice for airports, refineries, manufacturing plants, municipal fire departments, and other operations involving the transportation, processing, or handling of flammable liquids. It is available as 1%, 3%, and 6% concentrates or as 1% and 3% freeze-protected concentrates.

| Product Name | Download Link |

|---|---|

| Class B Hydrocarbons (AFFF) | Datasheet |

JET-X High-Expansion Foam Concentrates are flexible firefighting concentrates, used in fighting Class A, Class B, and LNG fires both indoors and outdoors. Expansion ratios from 50:1 up to 1000:1 make them suitable for a variety of applications including aircraft hangars, flammable liquid storage areas, and LNG facilities.

When used with high-expansion generators, JET-X High-Expansion Foam Concentrate can fill large areas, such as aircraft hangars, warehouses, ship cargo holds, mine shafts, and extinguish horizontal and vertical (three-dimensional) fires.

| Product Name | Download Link |

|---|---|

| Class A, B, & LNG Fires High-Expansion Foam | Datasheet |

Class A foam concentrates are specifically designed to combat fires involving ordinary combustible materials, like wood, paper, coal, rubber, and plastic by making water more effective. The concentrates reduce the surface tension of water providing superior wetting and penetrating characteristics. This allows the solution to penetrate deep into the char of deep seated fires, promoting cooling and making the Class A fuel less combustible. The expanded foam solutions also create a dense foam blanket that provides an insulating barrier between the fuel and the air.

The extended drain time of SILV-EX PLUS concentrate provides longer surface wetting and cooling of the fuel and reduces the risk of ignition or reignition. In addition, foams make water five times more effective on Class A fires and cling to vertical surfaces, providing structure protection.

| Product Name | Download Link |

|---|---|

| ANSUL-A Municipal Class A | Datasheet |

| SILV-EX Plus "Class A" | Datasheet |

Fluoroprotein foams provide better control, greater fluidity, and superior resistance to fuel contamination in comparison to standard protein foams. Fluoroprotein foams demonstrate good burnback resistance, are useful for hydrocarbon vapor suppression, and have been recognized as effective fire suppression concentrates for subsurface injection into hydrocarbon fuel storage tanks.

Fluoroprotein foams are derived from protein foam concentrates to which small amounts of fluorochemical surfactants are added. The fluorochemical surfactants are similar to those developed for AFFF foam concentrates but used in much lower concentrations. These surfactants provide an easier flowing foam and create oleophobicity (oil shedding properties) that make it well-suited for sub-surface injection.

| Product Name | Download Link |

|---|---|

| 3% Fluoroprotein Foam | Datasheet |

| 6% Fluoroprotein Foam | Datasheet |

TARGET-7 Vapor Mitigation and Neutralizing Agent provides for a single application to suppress dangerous vapor release from a chemical spill while also pH neutralizing the spilled material. When mixed with the appropriate neutralizing agent, the TARGET-7 concentrate may be used for chlorine dioxide, oleum, chlorosulfonic acids, sulfur trioxide, liquid ammonia, and other fuming acid spills. This is critical when time is of the essence after a dangerous spill of fuming acid or other hazardous chemicals.

Once TARGET-7 agent is applied and has formed its cover on the spill, there is no need to apply another neutralizing agent which would break the foam blanket. The foam blanket serves as the source for the neutralizing solution, acts to suppress vapor release from the spill and acts as a natural gas/vapor scrubber.

| Product Name | Download Link |

|---|---|

| Vapor Suppression | Datasheet |

Training Foam is not intended for live fire training or for actual firefighting operations. It is functional in any proportioning and generating equipment and minimizes the effects of training on the environment. In addition, the low cost of training foam over regular foam provides a cost effective alternative for training purposes. Expansion and drainage characteristics are similar to conventional 3% and 6% AFFF products.

| Product Name | Download Link |

|---|---|

| Training Foam 3% or 6% | Datasheet |

ANSUL Portable Equipment

Handline Nozzles can be used with a variety of foam concentrates for a variety of applications. The nozzles are constructed of corrosion resistant materials, and are lightweight for ease of handling.

Foam handline nozzle types available include air aspirating low expansion, medium expansion, and dual expansion (low/medium variable). Eductors create a foam solution by adding a percentage of foam concentrate into the pressurized water stream for the handline nozzles.

| Product Name | Download Link |

|---|---|

| Handline Nozzles and Eductors | Datasheet |

Depending on the type of hazard and its configuration, Portable High-Expansion Foam Generators may be used for total flooding applications involving three-dimensional hazards. The generators may also be used for local application on spill fires or for vapor suppression.

Water damage is minimized when using high expansion foam. Common applications for this equipment include warehouses, ship holds, engine rooms, machinery spaces, electric cable ducting, mining, communications switching rooms, basements, cellars and enclosed spaces, LNG spill fires and vapor suppression, and smoke extraction (with optional smoke extraction ducting).

| Product Name | Download Link |

|---|---|

| Portable High-Expansion Foam Generators | Datasheet |

The Foam Systems Mobilcart is designed to provide mobile firefighting foam capability for various hazardous areas where flammable liquids are present. Common applications include tank farms and refineries, loading areas, chemical processing plants, diked areas, warehouse facilities, paint storage areas, and other manufacturing areas where flammable liquids are a hazard.

A broad range of foam concentrates can be used for Class B applications including ANSULITE AFFF, Alcohol Resistant AFFF, JET-X high-expansion type, and protein based foam concentrates. For Class A fire hazards with wood, paper, coal, and rubber, SILV-EX concentrate proportioned at 1% is recommended.

| Product Name | Download Link |

|---|---|

| Foam Systems Mobilcart | Datasheet |

Trailers provide mobile fire protection for flammable liquid hazards typically found in such areas as refineries and associated tank farms, chemical processing plants, truck and rail car unloading facilities, and marine terminals. This portable equipment is extremely mobile and substantially increases the firefighting capabilities of industrial, municipal and military fire departments.

The trailer assembly axle(s), wheels and tires are designed to carry the gross weight of the trailer with associated equipment and foam concentrate. Model options include the Master Foam Tote Trailer, Dual Foam Tote Trailer and Proportioning Foam Trailer.

| Product Name | Download Link |

|---|---|

| Trailers | Datasheet |

ANSUL Discharge Devices

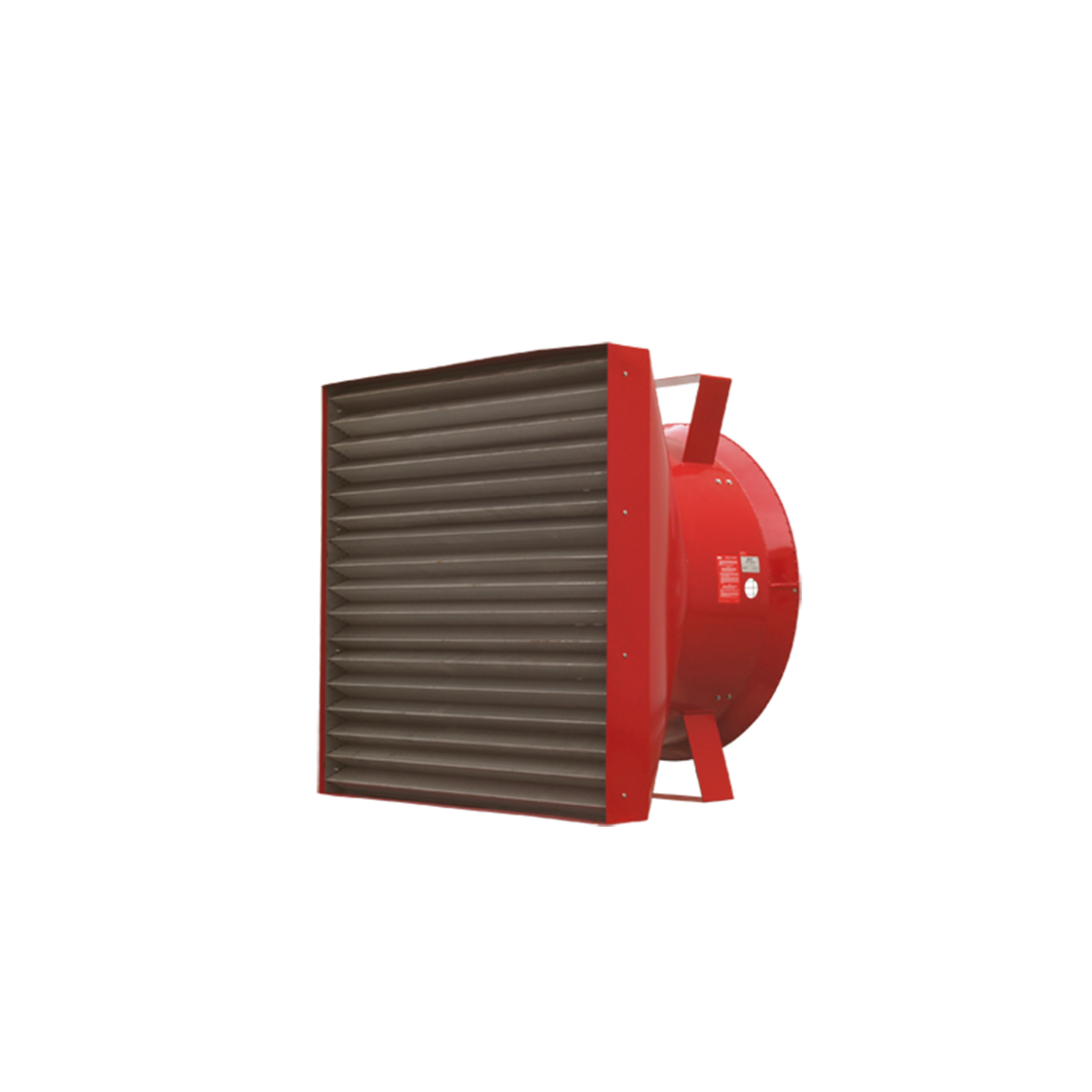

JET-X High-Expansion Foam Generators deliver large quantities of expanded foam by blowing air through a screen coated with a high-expansion foam solution. Because of its high expansion ratio (up to 1000:1), little water is required to generate large quantities of foam. This dramatically cuts the cost of these systems and has the additional benefit of reducing the system footprint.

The high and medium expansion foam systems offer a fire extinguishing procedure that overwhelms the fire with the sheer volume of foam. The foam blanket that is produced transports water to the fire, suffocates and cools the fire, suppresses escaping vapors and encapsulates the toxic vapors and particulate.

| Product Name | Download Link |

|---|---|

| High Expansion Generators | Datasheet |

Foam Chambers and Foam Makers are air-aspirating foam discharge devices designed to protect flammable liquid storage tanks by applying foam down the inside wall of the tank. Foam Chambers are designed to generate foam and apply the expanded foam to the fuel surface in a manner that lessens submergence and agitation as the foam contacts the fuel.

Foam Makers include High Back-Pressure, Floating Roof Foam Makers, and Rim Seal Foam Pourers. High Back-Pressure Foam Makers are designed to generate expanded foam for the purpose of subsurface injection into a cone-roof liquid hydrocarbon storage tank. Floating Roof Foam Makers (FLR) and Foam Pourers are air-aspirating foam discharge devices that are designed to protect floating roof, flammable liquid storage tanks.

| Product Name | Download Link |

|---|---|

| Storage Tank Protection Equipment | Datasheet |

Foam Monitors control the horizontal and vertical directions of large capacity discharge streams. Water-oscillating monitors automatically move side-to-side using water pressure as the energy source. Remote controlled monitors use an electric joystick to control horizontal, vertical and stream pattern. Other monitors are operated manually using a tiller bar or housewheel.

Many monitor model are available including manual, FJM (high flow), and water oscillating with a variety of nozzle options including master stream non-aspirated monitor nozzles, and AFN air-aspirating nozzles.

| Product Name | Download Link |

|---|---|

| Foam Monitors | Datasheet |

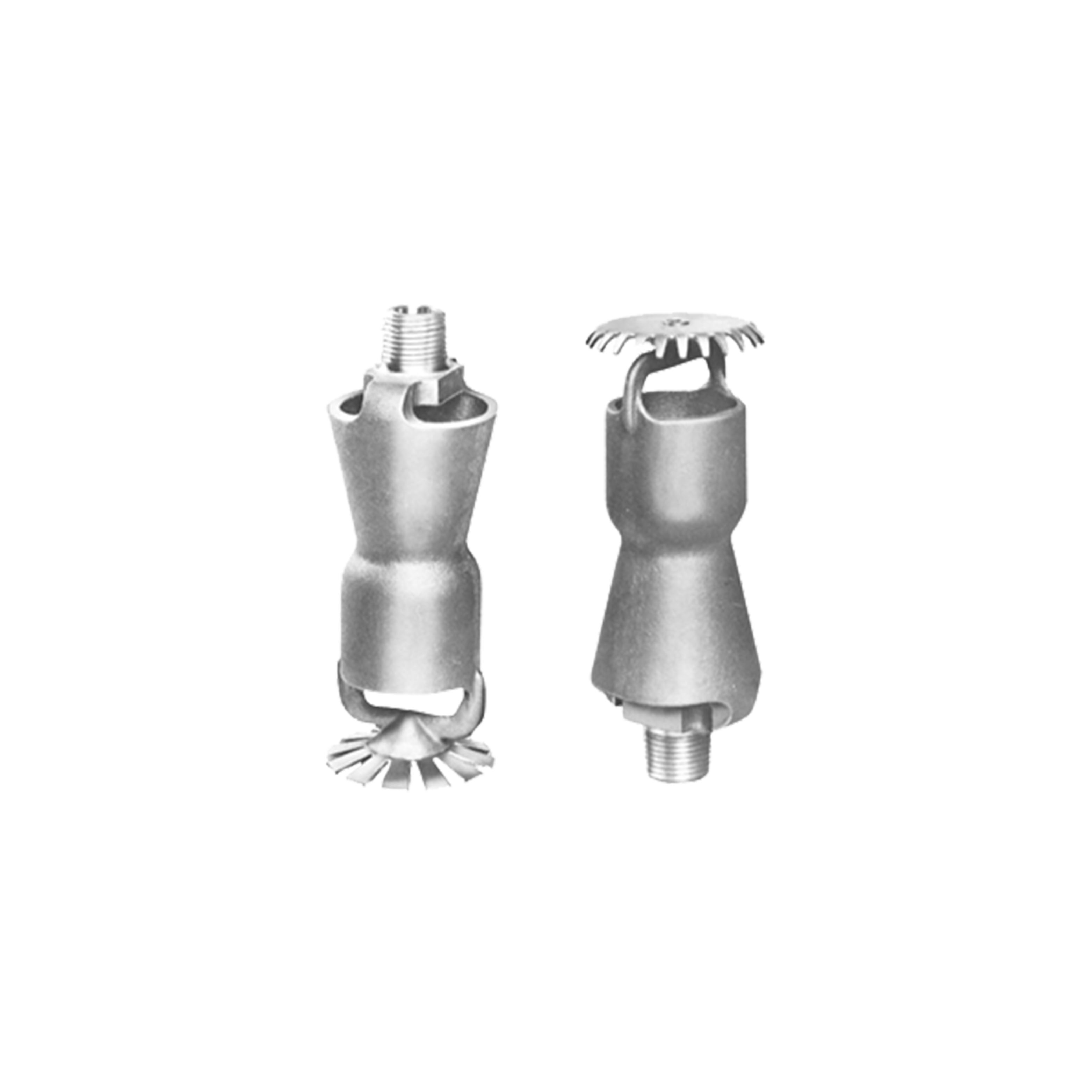

Sprinkler Heads are available in both aspirating and non-aspirating versions. Aspirated sprinkler heads are required for protein and fluoroprotein foams in deluge systems. Non-aspirated heads with AFFF agents are more economical and can be used in either open deluge or closed-head sprinkler systems. Sprinkler head types available include the B-1 Foam-Water and TF Foam Discharge.

| Product Name | Download Link |

|---|---|

| Sprinkler Heads | Datasheet |

ANSUL Proportioning Equipment

In the past, designing a pump proportioning system to protect a hazard with multiple zones has required numerous in-line balanced pressure proportioners (IBP) of various sizes. ANSUL FLOWMAX PPW Variable Range Proportioners represent a revolution in foam system design by eliminating the need for multiple IBPs.

| Product Name | Download Link |

|---|---|

| "NEW" FLOWMAX PPW Variable Range Proportioner | Datasheet |

Bladder Tanks are a component of a balanced pressure proportioning system that includes a pressure-rated tank with an internal elastomeric bladder for foam concentrate storage. Upon system actuation, incoming water applies pressure to the concentrate in the bladder, which supplies pressurized concentrate to the proportioning device. The device meters the foam concentrate into the fire water line, creating foam solution. The solution is then piped to the discharge devices protecting the hazard area.

| Product Name | Download Link |

|---|---|

| Bladder Tanks | Datasheet |

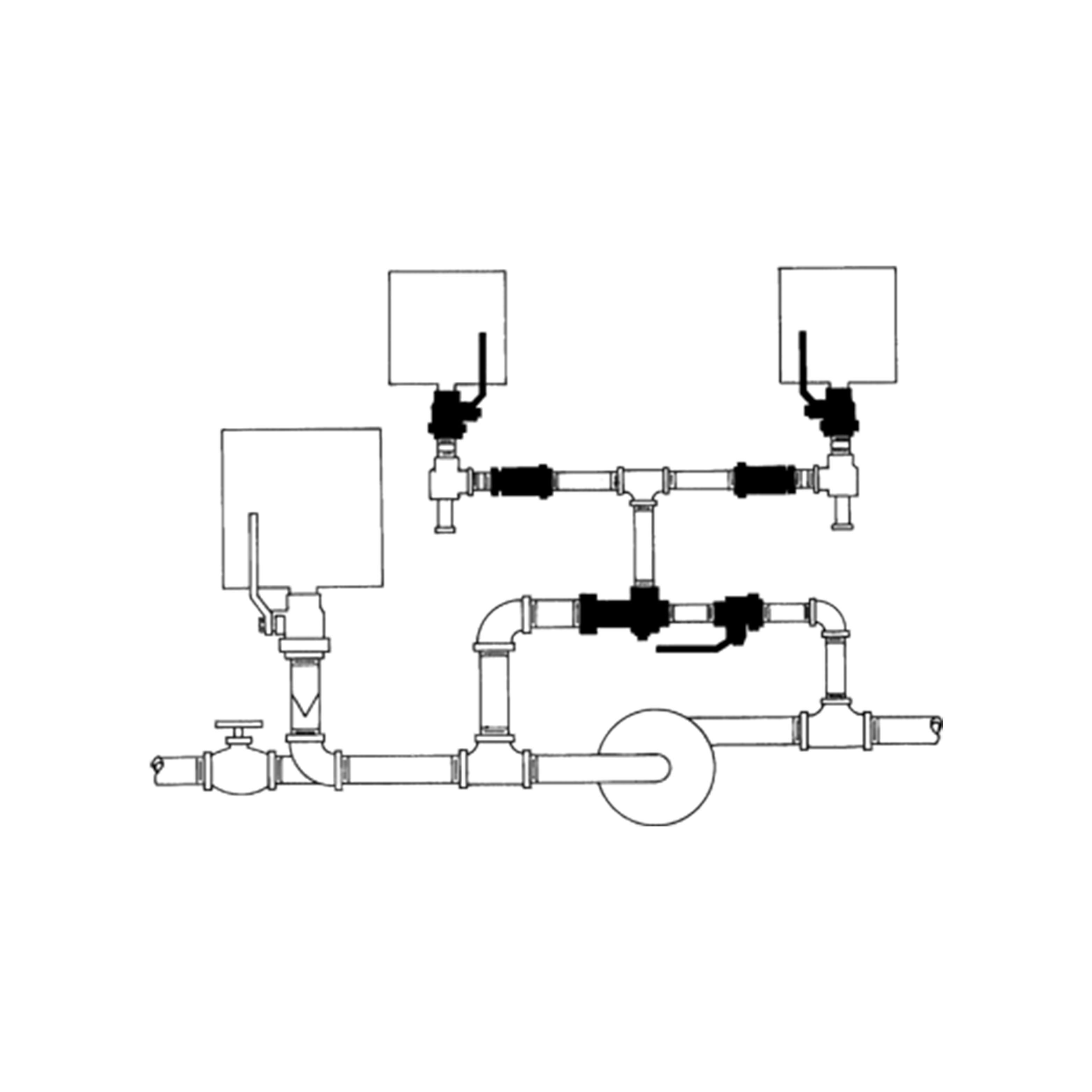

The Balanced Pressure Pump Proportioning System functions by maintaining an equal pressure in the foam concentrate and water inlets to the proportioner, allowing the proportioner to be used over a wide range of flows and pressures. The system connects to an atmospheric storage tank which allows refilling during operation. Controls respond quickly and accurately to changes in the water inlet pressures and flow rates.

The system operates by passing the required portion of foam concentrate from a positive displacement pump to a venturi proportioner with the remaining portion recirculating through a diaphragm valve in the return line to the tank. The diaphragm valve senses and balances the pressure (which can also be balanced manually) in the foam and water lines to the proportioner. The foam concentrate then enters the proportioner where a built-in orifice regulates the flow of pressurized foam concentrate entering the water stream.

| Product Name | Download Link |

|---|---|

| Pump Skids | Datasheet |

Proportioning Equipment introduces a foam concentrate into a flowing stream of water to produce a foam solution. There are many methods of proportioning, but fixed foam systems typically use balanced pressure proportioning equipment such as the In-Line Balanced Pressure Proportioner. This proportioner is similar to a pump skid except it is a separate assembly that offers the advantage of proportioning the foam concentrate at a location remote from the tank and pump.

In-line balanced pressure proportioners are used with an atmospheric foam concentrate tank and a positive displacement foam concentrate pump. They are designed to accurately control the flow of a foam liquid concentrate into a water stream over a wide range of flow rates and pressures. These devices can be used with all types of ANSUL foam concentrates.

| Product Name | Download Link |

|---|---|

| In-Line Balanced Pressure Proportioners | Datasheet |

Sprinkler Heads are available in both aspirating and non-aspirating versions. Aspirated sprinkler heads are required for protein and fluoroprotein foams in deluge systems. Non-aspirated heads with AFFF agents are more economical and can be used in either open deluge or closed-head sprinkler systems. Sprinkler head types available include the B-1 Foam-Water and TF Foam Discharge.

| Product Name | Download Link |

|---|---|

| Line Proportioners | Datasheet |

Proportioning Equipment introduces the foam concentrate into a flowing stream of water to produce a foam solution. There are many methods of proportioning, but fixed foam systems typically use balanced pressure proportioning equipment. All balanced pressure systems use a modified venturi device called a proportioner or ratio controller.

Proportioners are available in a variety of sizes and styles to match required flow ranges and pipe sizes. Each proportioner consists of a body, inlet nozzle, and metering orifice—all of which are corrosion-resistant brass. Proportioners are UL listed and FM approved with certain foam concentrates and used in conjunction with bladder tanks and pump proportioning skids. Typical applications include flammable liquid storage tanks, loading racks, aircraft hangars, heliports, and anywhere flammable liquids are used, stored, processed or transported.

| Product Name | Download Link |

|---|---|

| Proportioners | Datasheet |

Around-The-Pump Proportioning Systems provide a simple and effective means to introduce a foam concentrate at the desired percentage to the water being discharged in a fire pump system. The number of different foam concentrates is only limited by available space as each concentrate requires a separate tank.

The types of foam concentrates typically include ANSULITE AFFF of either 1%, 3%, or 6%; ANSULITE AR-AFFF of either 3X3 LV or ARC types; or SILV-EX Class A foam concentrate. A fire truck pumper system may have a dual proportioning system with one tank having a Class B foam concentrate for flammable liquid fires and a second tank having Class A foam concentrate for structural fire attack or other ordinary combustible fire materials.

| Product Name | Download Link |

|---|---|

| Around-The-Pump Proportioning Systems | Datasheet |

ANSUL Clean Agent Systems

Traditionally, SAPPHIRE Clean Agent Fire Suppression Systems boast a proven record for protecting people, the environment and high value assets. Next generation SAPPHIRE PLUS 70-Bar Systems offer additional benefits.

Both systems are custom engineered to quickly suppress fires in occupied areas without causing harm and where clean-up of other agents may pose a problem. SAPPHIRE PLUS systems help reduce the footprint, installation cost and service time by offering higher fill densities to reduce the number of containers. The increased pressure also permits the containers to be located much further from the protected space and increases the ability to introduce selector valves to protect multiple hazards from a single container bank. Additionally, pipe sizes may be reduced, thereby increasing the economy and design flexibility.

| Product Name | Download Link |

|---|---|

| SAPPHIRE® PLUS 70-Bar System | Datasheet |

The ANSUL® SAPPHIRE COMPACT Direct Low Pressure (DLP) Fixed Fire Suppression System has been specifically designed to protect small electrical enclosures. A self-contained system, it requires no power for either detection or operation and protects enclosures that use either natural ventilation or forced airflow. One system can protect up to four enclosures and each enclosure can contain multiple compartments.

| Product Name | Download Link |

|---|---|

| SAPPHIRE® COMPACT Direct Low Pressure System | Datasheet |

Using innovative iFLOW delivery technology, the INERGEN® 300-Bar Clean-Agent Fire Suppression System provides a regulated agent discharge into the protected hazard area.

INERGEN agent is composed of naturally-occurring gases found in the air we breathe. Unlike other inert gas agents, INERGEN agent includes a small percentage of carbon dioxide which enhances its ability to sustain life in a reduced oxygen atmosphere. INERGEN agent is nontoxic, does not produce corrosive decomposition products when exposed to fire and is designed to protect valuable or sensitive assets that could be damaged by conventional agents. When discharged, it will not produce a fog, so escape routes will remain visible. And in the aftermath of an incident, the agent simply returns to the atmosphere in its natural state causing no environmental impact.

| Product Name | Download Link |

|---|---|

| INERGEN Systems – 300-Bar iFLOW Technology | Datasheet |

The INERGEN Fire Suppression System protects enclosed areas where people may be present, fire may strike day or night, and damage from conventional agents cannot be tolerated. Upon discharge, INERGEN agent fills the room, mixing with the air to suppress fires quickly and effectively. Safe for people, INERGEN agent is non-synthetic and made of naturally occurring gases: nitrogen, argon, and carbon dioxide. Once discharged, it returns to the atmosphere in its natural state.

INERGEN agent is free of residues and corrosive by-products that may produce further property damage. And because it poses no ozone depleting or global warming threat,INERGEN agent will never be subject to future legislative bans.

| Product Name | Download Link |

|---|---|

| INERGEN Systems – 150-Bar | Datasheet |

| INERGEN Systems – 200-Bar | Datasheet |

Data Centers and server rooms are continuously improving their efficiencies to store and process more data. Improvements in computing hardware have led to an increase in Hard Disk Drive (HDD) sensitivity to sound. Gaseous fire suppression systems, normally used to protect this type of equipment, can produce sound levels that may have adverse effects on noise sensitive equipment.

The ANSUL® Acoustic Nozzle, in combination with an INERGEN® or SAPPHIRE® Fire Suppression System, is particularly useful for suppressing fires in hazards where sound levels may affect sensitive electronic equipment as found in server rooms and data centers. The nozzle reduces the sound power level compared with standard nozzles and offers exceptional area coverage. It is suitable for use with existing hydraulic flow calculation software and available with both NPT and BSP connection threads.

| Product Name | Download Link |

|---|---|

| Acoustic Discharge Nozzle | Datasheet |

Using water as a fire suppressant in areas where electronics operate and irreplaceable, high-value assets are stored, could be as devastating as fire itself. The SAPPHIRE Clean Agent System quickly suppresses fires and protects sensitive equipment without causing harm to people or the environment. The system is especially suited to suppress fires in areas where an electrically non-conductive medium is required, where electronic systems cannot be shut down in an emergency, where cleanup of other agents poses a problem, and in normally occupied areas that demand a non-toxic agent.

The SAPPHIRE system uses 3M Novec 1230 fire protection fluid for total flooding applications. The clear, colorless agent has zero ozone depletion potential, an atmospheric lifetime of just five days, and a global warming potential of 1.0. The SAPPHIRE system suppresses a fire before it can be fully engaged and once the fire is suppressed, Novec 1230 quickly evaporates without harming any valuable assets.

| Product Name | Download Link |

|---|---|

| SAPPHIRE Systems | Datasheet |

The ANSUL FM-200 Clean Agent Fire Suppression System is approved by Factory Mutual (FM) and listed by Underwriters Laboratories (UL) for Class A, B and C fires. Safe for use in occupied areas at the design concentration, the system helps protect critical infrastructure and delivers effective asset protection.

The system uses FM-200 (HFC-227ea) fire extinguishant which has zero ozone depletion (ODP). This colorless, odorless agent vaporizes upon discharge and absorbs heat to rapidly suppress fire while leaving no residue to clean up. It is electrically nonconductive, will not short-out electronic equipment or thermally shock delicate circuitry resulting in less damage to critical equipment, facilitating a much shorter recovery time and reducing downtime.

| Product Name | Download Link |

|---|---|

| FM-200 Systems | Datasheet |

ANSUL Agent Releasing Panels

AUTOPULSE detection, control and fire suppression system releasing panels provide automatic 24/7 fire protection. Agent Releasing Control Panels are designed with modularity and easy system planning. The panels can be configured with just a few devices for small building applications or for a large campus or high-rise application. Peripheral equipment can be added to suit the application. See "Options" Tab for details.

| Product Name | Download Link |

|---|---|

| Analog Addressable Releasing Systems | Datasheet |

AUTOPULSE detection, control and fire suppression system release panels provide automatic 24/7 fire protection. Detection options include smoke, heat and flame detection. The control panels process detection signals from protected areas and immediately perform key operations including sounding alarms, shutting down equipment and releasing the fire suppression system.

Accessories include smoke/heat/flame detectors, manual pull stations, horns, strobes, bells, abort switches, maintenance switches, and more.

| Product Name | Download Link |

|---|---|

| Conventional Releasing Systems | Datasheet |

VESDA aspirating smoke detectors buy the critical time needed to investigate an alarm and initiate an appropriate response to prevent injury, property damage or business disruption. VESDA detectors have multi-level warnings and a wide range of sensitivity where minute levels of smoke can be detected before a fire has time to escalate. VESDA detectors accommodate a broad range of environments and applications: small to very large open spaces and cleanest to dirty environments.

| Product Name | Download Link |

|---|---|

| Xtralis VESDA VLC | Datasheet |

| Xtralis VESDA VLF-500 | Datasheet |

| Xtralis VSM4 | Datasheet |

| VESDAnet™ Interface Card (VIC-010) | Datasheet |

| Xtralis VESDA VLF MCC (VIC-020 & VIC-030) | Datasheet |

| Xtralis VESDA VLP | Datasheet |

| Xtralis VESDA LCD Programmer | Datasheet |

| Xtralis VESDA VLS | Datasheet |

| Xtralis VESDA VLS Display Modules | Datasheet |

| Xtralis VESDA 19" Subrack Enclosure | Datasheet |

| Xtralis VESDA Power Supply | Datasheet |

| Xtralis VESDA VLI | Datasheet |

| Xtralis VESDA VFT-15 | Datasheet |

ANSUL Carbon Dioxide Systems

Carbon dioxide suppresses fire without leaving behind any residues after discharge thus avoiding damage to sensitive equipment. With no agent clean up, there is less downtime after an incident. When properly designed, the carbon dioxide system will suppress fire in Class A, B, and C hazards by displacing the air containing oxygen that supports combustion. Typical hazards protected by carbon dioxide systems include printing presses, vaults, open pits, dip tanks, spray booths, ovens, engine rooms, coating machines, process equipment, hoods and ducts, flammable gas or liquid storage areas, and generators.

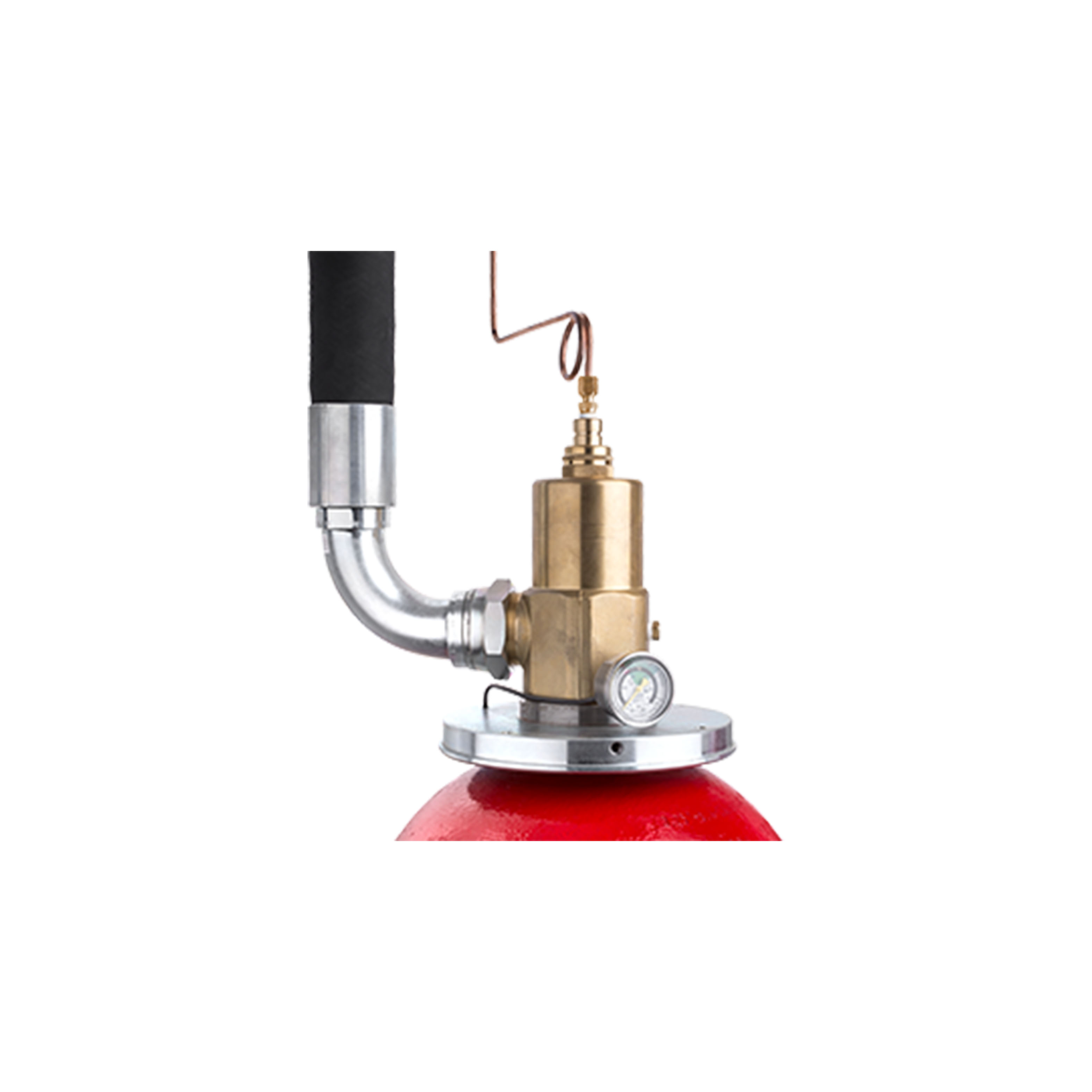

The High Pressure Carbon Dioxide System is especially effective for non-occupied hazards. Personnel occupying areas protected by carbon dioxide systems must be evacuated prior to system discharge. Therefore, discharge time delays and alarms are mandatory for occupied hazards. Whatever the application, from cylinder to nozzle, each system can be custom-designed for specific fire hazards. High pressure systems use individual storage cylinders—from 35 lb. (16 kg) to 120 lb. (54 kg) capacity each—that can be manifolded together for rapid simultaneous discharge. Cylinder valves can be opened automatically or manually and either locally or remotely using electric, pneumatic or mechanical valve actuators.

| Product Name | Download Link |

|---|---|

| High Pressure Carbon Dioxide Systems | Datasheet |

Bridging the gap between high pressure cylinders and low pressure bulk tanks, mini-bulk tanks offer capacities of 1,000 and 1,500 lb (454 and 680 kg). The Mini-Bulk Low Pressure Carbon Dioxide Systems provide an alternative to manifolding high pressure cylinders. The tanks are configured vertically to save valuable floor space. Mini-bulk tanks provide protection for non-occupied total flood, local application hazards, hose reels or custom designs such as inerting or spurt systems.

Each mini-bulk tank is equipped with a low-cost, high-efficiency, air-cooled refrigeration unit. The refrigerant media, R134a, is environment-friendly and efficient. Most system components are interchangeable between the mini-bulk system and the larger bulk storage tank system. Typical hazards protected by carbon dioxide systems include printing presses, transformer vaults/electrical cabinets, open pits, dip tanks, rolling mills, ovens, coating machines, process equipment, exhaust and fume handling systems, flammable gas or liquid storage areas, generators, and inerting applications.

| Product Name | Download Link |

|---|---|

| Mini-Bulk - Low-Pressure | Datasheet |

The Bulk Low Pressure Carbon Dioxide Systems are ideal for non-occupied fire hazards requiring large amounts of extinguishing agent in a limited space. A single bulk tank can store from 3 3/4 to 46 tons (680 to 41,730 kg) of carbon dioxide, which is maintained in a stand-by fire-ready state that allows the system to provide effective distribution of agent on demand. Bulk low pressure CO2 systems offer multiple discharge capabilities between recharges as an economical option.

The liquid CO2 is stored in an ASME-coded pressure vessel equipped with its own refrigeration system. The temperature within the vessel is kept at approximately 0 °F (-18 °C) by maintaining the internal pressure near 300 psi (20.7 bar). Valve control is electro-pneumatic or manual. Each master and selector valve assembly consists of either a ball or a butterfly valve, a spring-return pneumatic valve operator and a three-way electronically operated solenoid valve. Typical hazards protected by carbon dioxide systems include printing presses, transformer vaults/electrical cabinets, open pits, dip tanks, rolling mills, ovens, coating machines, process equipment, exhaust and fume handling systems, flammable gas or liquid storage areas, generators and inerting applications.

| Product Name | Download Link |

|---|---|

| Bulk-Low Pressure Carbon Dioxide Systems | Datasheet |

ANSUL Water Atomizing

The AQUASONIC Water-Atomizing Fire Suppression System is a revolution in Class B fire protection technology. The high performance fire suppression system is specifically engineered to protect special hazard applications including combustion turbine enclosures, machinery spaces, generator enclosures, and flammable liquid storage areas.

The system utilizes non-toxic and readily available extinguishing media (water and nitrogen). Two supersonic atomizers create 1.5 trillion superfine water droplets per second, producing a combined surface area of 1302 ft2 (121.0 m2) per second. This is equivalent to the surface of an Olympic-size soccer field in one minute. Plus, the atomizers propel the droplets at high velocity throughout the combustion zone. The AQUASONIC atomizer features 100% machined stainless steel construction for superior strength, no internal moving parts for extreme dependability, and multiple mounting options for ease of installation.

| Product Name | Download Link |

|---|---|

| AQUASONIC System |

ANSUL Industrial Systems

Carbon dioxide suppresses fire without leaving behind any residues after discharge thus avoiding damage to sensitive equipment. With no agent clean up, there is less downtime after an incident. When properly designed, the carbon dioxide system will suppress fire in Class A, B, and C hazards by displacing the air containing oxygen that supports combustion. Typical hazards protected by carbon dioxide systems include printing presses, vaults, open pits, dip tanks, spray booths, ovens, engine rooms, coating machines, process equipment, hoods and ducts, flammable gas or liquid storage areas, and generators.

The High Pressure Carbon Dioxide System is especially effective for non-occupied hazards. Personnel occupying areas protected by carbon dioxide systems must be evacuated prior to system discharge. Therefore, discharge time delays and alarms are mandatory for occupied hazards. Whatever the application, from cylinder to nozzle, each system can be custom-designed for specific fire hazards. High pressure systems use individual storage cylinders—from 35 lb. (16 kg) to 120 lb. (54 kg) capacity each—that can be manifolded together for rapid simultaneous discharge. Cylinder valves can be opened automatically or manually and either locally or remotely using electric, pneumatic or mechanical valve actuators.

| Product Name | Download Link |

|---|---|

| S-CR-LR-K-350-C Stationary Dry Chemical System | Datasheet |

| FORAY Dry Chemical Suppressing Agent | Datasheet |

| PLUS-FIFTY C Dry Chemical Suppressing Agent | Datasheet |

| Purple-K Dry Chemical Suppressing Agent | Datasheet |

| Remote Hose Reel Assemblies with Manual Rewind | Datasheet |

| Hand Hose Line Stationary Dry Chemical System | Datasheet |

| Model S-150-C & S-350-C Stationary Fire Extinguishers | Datasheet |

The Dry Chemical Piped Fire Suppression Systems are designed to provide full-time fire protection in high-risk areas where large, potentially disastrous fires could occur. They use proven technology for fast knock down of the toughest flammable liquid and gas fires and provide a means of detection and suppression for complex hazards that are too difficult and inaccessible for manual means of firefighting.

Typical applications include petroleum and petrochemical loading racks, refinery processing equipment, product transfer and storage areas and offshore platforms; marine tanker decks, machinery spaces and loading docks; paint spray booths, dip and quench tanks, warehouses, hazardous materials storage buildings, machinery lubricating systems, and flammable liquid storage areas; and many other settings. For large industrial applications, large fixed nozzle piped systems provide up to 3000 lb. (1360.8 kg) of dry chemical extinguishing agent.

| Product Name | Download Link |

|---|---|

| Dry Chemical Fixed Pipe Fire Suppression System General Specifications | Datasheet |

| Dry Chemical Fixed Pipe Fire Suppression Systems Accessories | Datasheet |

| PLUS-FIFTY C Dry Chemical Suppressing Agent | Datasheet |

| Dry Chemical Discharge Nozzles | Datasheet |

Extremely hazardous fires require top-level skills and innovative agents. Twin-Agent Fire Suppression Systems provide proven technology to fight large flammable liquid and gas fires. Twin-agent technology combines the fast flame knockdown of a dry chemical with the fire securing capabilities of aqueous film-forming foam. The twin-agent attack provides the most effective extinguishing and securing capability known for many flammable liquid fires. Industries that benefit most from the system include petroleum and petrochemical, marine, natural gas, and aviation.

The Twin-Agent System combines two proven, powerful agents: Purple-K dry chemical agent and ANSULITE AFFF. A potassium bicarbonate-based dry chemical, Purple-K provides rapid knockdown and suppression of flammable liquid fires. ANSULITE AFFF is synthetic, aqueous film-forming foam that blankets the fuel with a thin film, preventing the escape of flammable vapors and cooling the site.

| Product Name | Download Link |

|---|---|

| 100/30 Self-Contained Twin-Agent Hand Hose Line System | Datasheet |

| Model S-150-C & Model S-350-C Stationary Fire Extinguishers | Datasheet |

| Twin-Agent Nozzle (Over/Under Model) | Datasheet |

| Hand Hose Line Stationary Dry Chemical System | Datasheet |

| S-CR-LR-K-350-C Stationary Dry Chemical System | Datasheet |

| PLUS-FIFTY C Dry Chemical Suppressing Agent | Datasheet |

| Purple-K Dry Chemical Suppressing Agent | Datasheet |

ANSUL Portable Extinguishers

Stored Pressure

SENTRY dry chemical extinguishers are designed for protection of light and ordinary hazards. These compact and portable extinguishers are suited for both industrial and commercial fire protection needs.

| Product Name | Download |

|---|---|

| SENTRY Powder Australian Hand Portable Extinguisher | Datasheet |

| Dry Chemical Hand Portable Fire Extinguishers | Datasheet |

SENTRY High-Flow, Stored-Pressure Fire Extinguishers are designed specifically for commercial, compliance markets. This portable fire extinguisher provides cost-effective, high performing fire suppression to meet the requirements of NFPA 10 Standard for Portable Fire Extinguishers.

| Product Name | Download Link |

|---|---|

| SENTRY High-Flow Stored-Pressure Fire Extinguishers | Datasheet |

SENTRY industrial dry chemical extinguishers are designed for protection of light, ordinary, and extra high hazards. These compact and portable extinguishers meet the needs for industrial fire protection and are built to survive the corrosive environments found in the mining and chemical industry or in marine environments.

| Product Name | Download Link |

|---|---|

| SENTRY Corrosion Resistant | Datasheet |

Every year, a variety of incidents leads to fires that costs businesses their critical assets. SENTRY carbon dioxide extinguishers provide the power to respond quickly and effectively by design to protect against Class B (flammable liquids and gases) and Class C (energized electrical equipment) fires. These extinguishers are well suited for indoor use in furnace rooms, printing presses, pump rooms, electrical power panels, and laboratories where winds and drafts do not affect discharge.

| Product Name | Download Link |

|---|---|

| SENTRY Carbon Dioxide Extinguishers | Datasheet |

SENTRY Water Extinguishers are designed to extinguish Class A hazards only. Class A hazards such as wood, cloth, trash, and other materials that leave an ash are often found in office environments and industrial locations, as well as warehouse and oxidizing chemical storage areas.

| Product Name | Download Link |

|---|---|

| SENTRY Water Extinguishers | Datasheet |

SENTRY dry chemical fire extinguishers are designed for the protection of light and ordinary hazards. These compact, portable extinguishers are suited for both industrial and commercial fire protection needs. They are ideal for auto repair shops, electrical equipment rooms, machining operations, material handling vehicles, banks, office, schools, hotels, warehouses, and many other applications.

| Product Name | Download Link |

|---|---|

| SENTRY and CLEANGUARD Low Profile Fire Extinguishers | Datasheet |

ANSUL Portable Extinguishers

Wheeled Units

RED LINE Wheeled dry chemical fire extinguishers are made specifically to protect people and property in areas where the potential for large-scale fires is always present. Airports, loading docks, steel and iron mills, paint spray booths, dip and quench tanks, offshore platforms, loading racks, fuel storage, and heavy manufacturing areas benefit from the protection offered by these industrial high-hazard fire extinguishers

| Product Name | Download |

|---|---|

| RED LINE CR-I-K-350-C | Datasheet |

SENTRY Carbon Dioxide Wheeled Fire Extinguishers are designed to protect areas where Class B (flammable liquids and gases) or Class C (energized electrical equipment) fires could occur. They may be used indoors where winds and drafts do not affect discharge or where a clean extinguishing agent is required. These extinguishers provide maximum protection in settings such as aircraft hangars, paint spray booths, quench tanks, and metal tube manufacturing.

| Product Name | Download Link |

|---|---|

| SENTRY Wheeled Units Carbon Dioxide | Datasheet |

ANSUL Portable Extinguishers

Cartridge Operated

RED LINE cartridge-operated fire extinguishers are the premium firefighting units preferred by safety directors worldwide in high fire-risk industries such as chemical, petro-chemical, oil and gas, mining, aviation, and power generation. Cartridge-operated means increased reliability, on-the-spot recharge, ease of service, and superior firefighting performance.

Typical applications include fuel loading racks, heavy construction sites, dip tanks, oil pumping stations, mining equipment, paint lockers, trucks and buses, fuel storage rooms, production lines and others. Tough, carbon steel shells resist impact, vibration and corrosion; quality components stand up to years of service; and special polyester powder paints provide superior protection against cracking and chipping.

| Product Name | Download |

|---|---|

| Model 20-G-E (CE/PED, EN-3) | Datasheet |

ANSUL Portable Extinguishers

Clean Agent Portables

CLEANGUARD Clean Agent Extinguishers are designed for the protection of commercial and industrial facilities that typically contain sensitive or irreplaceable equipment and materials that could be damaged or destroyed by water, foam, dry chemical, or carbon dioxide. Offering superior performance, CLEANGUARD extinguishers are electrically nonconductive, environmentally friendly, and extremely low in toxicity.

CLEANGUARD extinguishers are ideal for computer centers, data/document storage areas, communications facilities, control rooms, electronics manufacturing, laboratories, museums, art galleries, and more. Rated for Class A, B, and C fires, the extinguisher agent leaves no residue, requires no cleanup after discharge, and will not cause collateral damage to materials, equipment, and facilities.

| Product Name | Download |

|---|---|

| CLEANGUARD Clean Agent Extinguishers | Datasheet |

CLEANGUARD MR Conditional Extinguishers offer many of the same features as the standard CLEANGUARD Clean Agent Extinguishers but are made for environments where MR Conditional extinguishers are required, such as magnetic imaging rooms, semiconductor fabrication facilities, and similar applications.

Rated for Class A, B, and C fires, these extinguishers are ideal for hazard areas that require a reliable and safe non-magnetic fire extinguisher. The extinguishing agent is proven to be electrically non-conductive and will not damage sensitive electrical equipment like computers. It leaves no residue, requires no clean-up, has no ozone depletion potential, and is lower in toxicity compared to comparable agents.

| Product Name | Download Link |

|---|---|

| CLEANGUARD MR Conditional Extinguishers | Datasheet |

ANSUL Portable Extinguishers

Restaurant Portables

Choose ANSUL K-GUARD as your preferred restaurant fire extinguisher and meet NFPA 10 solid fuel cooking requirements for a firebox size of 5 ft3 or less. This upgraded 2-A rating also means compliance with NFPA 10 fire extinguisher size and placement for Class A Hazards which means you can protect the kitchen area without additional extinguishers needed.

K-GUARD extinguishers contain ANSULEX Low pH Liquid Fire Suppressant, a specially formulated, aqueous solution. In addition to knocking down the flame and forming a vapor-securing blanket, ANSULEX agent provides a cooling effect that aids in extinguishment and securement of hot cooking fuels. (ANSUL Low pH agent is used in both the K-GUARD extinguishers and R-102 restaurant fire suppression systems.)

| Product Name | Download |

|---|---|

| K-GUARD Fire Extinguisher | Datasheet |

The F-Class fire extinguishers meet the requirements of EN3 and PED for use on fires involving combustible vegetable or animal fats in commercial cooking equipment. The low pH fire extinguishing agent used in the extinguisher is a specially-formulated aqueous solution. It has been developed to provide rapid flame extinguishment and securement of hot fuels such as cooking shortenings.

Applications include kitchen cooking equipment typically found in restaurants, hospitals, nursing homes, hotels, schools, airports and other facilities. Appliances that benefit from F-Class protection include fryers; griddles; range tops; upright, natural charcoal, or chain-type broilers; electric, lava rock, mesquite or gas-radiant char-broilers; and woks.

| Product Name | Download Link |

|---|---|

| F-CLASS Liquid Agent Fire Extinguisher | Datasheet |

ANSUL Restaurant Systems

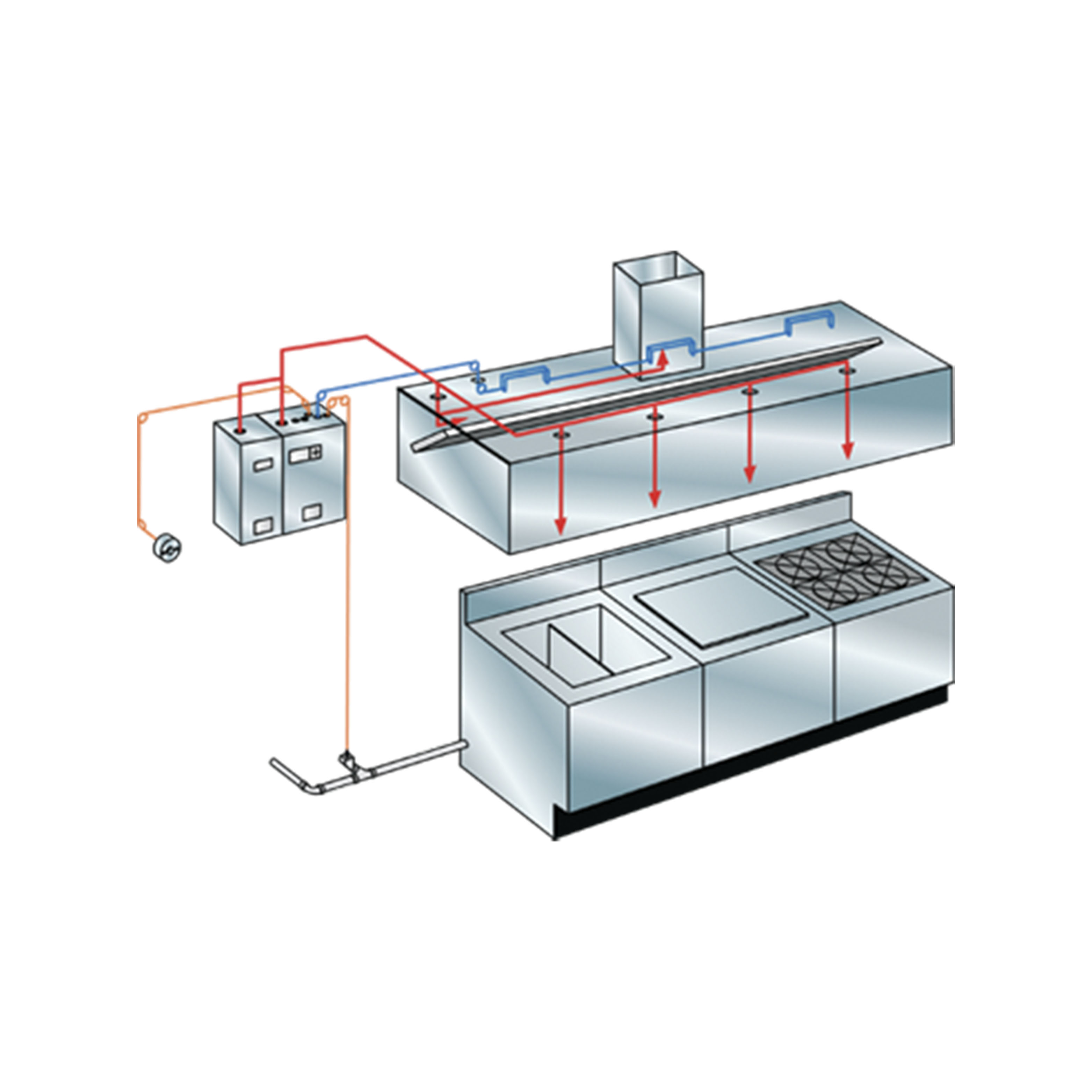

ANSUL products protect more food service kitchens from fire than any other brand. The R-102 Fire Suppression System incorporates a flexible design with an extremely effective ANSULEX Low pH Liquid Agent. ANSULEX quickly knocks down flames and cools hot surfaces, while generating a tough vapor securing blanket that helps prevent re-flash.

The R-102 system is designed to protect areas associated with ventilating equipment, including hoods, ducts, plenums, and filters. It also protects auxiliary grease extraction equipment and cooking equipment such as various types of fryers, griddles, range tops, broilers, char-broilers and woks. The system is ideally suited for commercial kitchens in fast food chains, retail food courts, diners, convenience stores, catering facilities, mobile food trucks, hotels and casinos, stadiums, schools, hospitals and more.

| Product Name | Download |

|---|---|

| R-102 Restaurant Fire Suppression System | Datasheet |

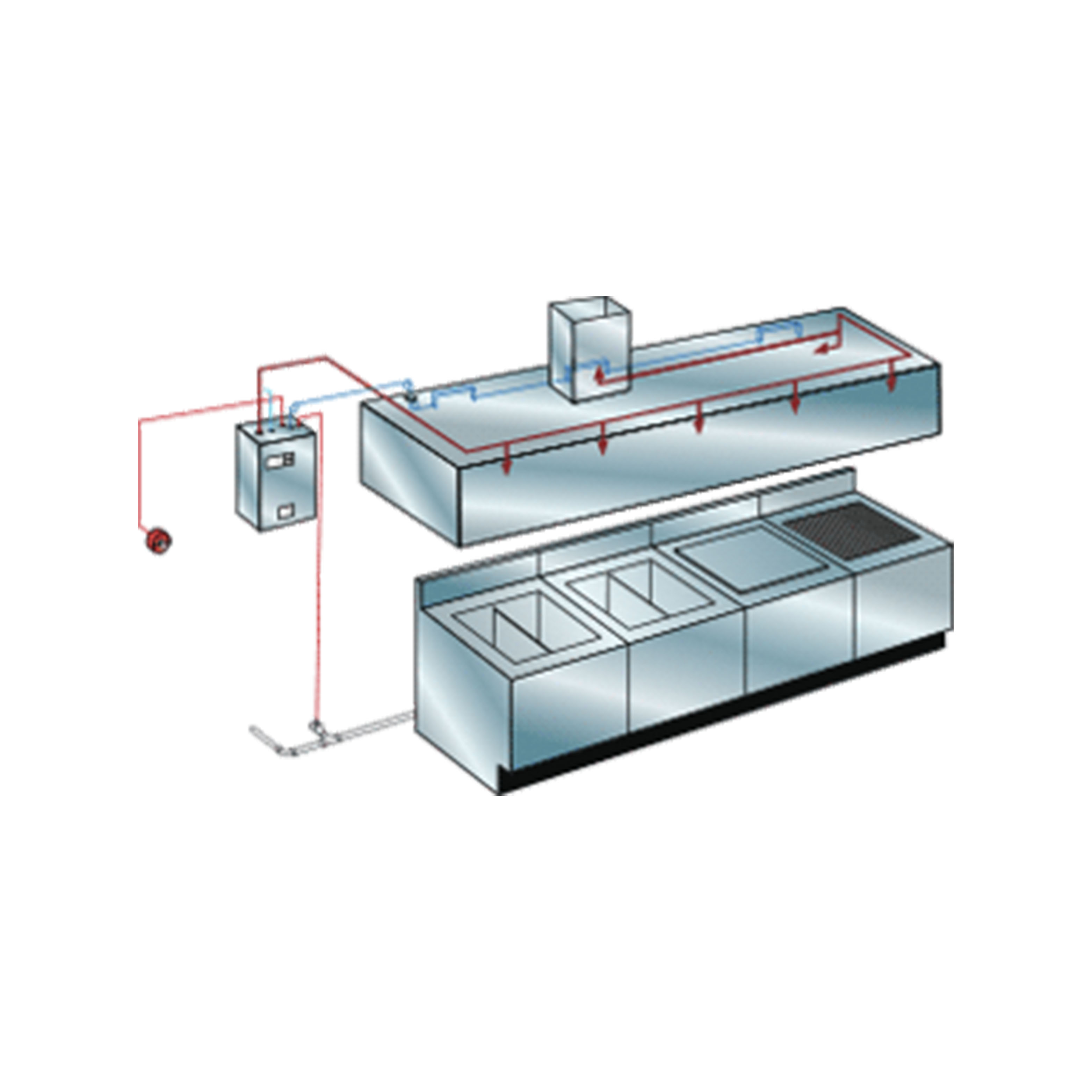

The PIRANHA Dual Agent Restaurant Fire Suppression System employs the best firefighting attributes of two extinguishing agents: the fast flame knockdown and securing power of wet chemical and the fast cool-down capability of water. The system provides protection for settings such as casual and fine dining, fast food chains, culinary schools, sports complexes and stadiums, and four- and five-star lodging facilities.

The only agent-plus-water fire suppression hybrid on the market today, the PIRANHA System outperforms all conventional single-agent systems. The system attacks fire using the rapid flame knockdown and the securing capabilities of PRX Liquid Fire Suppressant. After that, water follows, quickly cooling the cooking media and further helping to prevent reflash.

| Product Name | Download Link |

|---|---|

| PIRANHA Dual Agent Restaurant Fire Suppression System | Datasheet |

Overlapping Appliance Protection is one of the two design options available with the R-102 Restaurant Fire Suppression System. The design is flexible and simple. Nozzles are installed in a straight line with a maximum nozzle spacing of 25.5 in. (647 mm) and a height of 40-45 in. (1016-1143 mm) above the cooking surface. The nozzles are not aimed individually at specific appliances but instead are aimed at the hazard zone centerlines. These overlapping discharge patterns create a continuous zone of protection in which all appliances within this area are protected.

The R-102 system discharges ANSULEX Liquid Fire Suppressant, which quickly knocks down flames and cools hot surfaces, while generating a tough vapor securing blanket that helps prevent reflash. The R-102 system is designed to protect areas associated with ventilating equipment, including hoods, ducts, plenums, and filters. It also protects auxiliary grease extraction equipment and cooking equipment such as various types of fryers, griddles, range tops, broilers, char-broilers, and woks.

| Product Name | Download Link |

|---|---|

| ANSULEX Low pH Liquid Fire Suppressant | Datasheet |

High proximity nozzles now offered with PIRANHA systems help to meet the need for more aesthetically pleasing cooking and dining environments. The new UL listed nozzle design allows appliance protection nozzles to be installed up to 84 in. (2133 mm) above the cooking hazard, nearly flush with the top of the hood, and out of view while providing the same reliable protection that PIRANHA systems have always offered.

Common applications for PIRANHA systems include airports, casual and fine dining restaurants, catering facilities, culinary schools, expo kitchens, four- and five-star lodging facilities, hospitals, nursing homes, sports complexes and stadiums.

| Product Name | Download Link |

|---|---|

| PIRANHA - Increased Nozzle Heights | Datasheet |

ANSUL RED Technology

ANSUL Restaurant Electric Detection (RED) Technology is an electric, fully supervised and monitored technology designed to work with ANSUL R-102 and PIRANHA Fire Suppression Systems. ANSUL® RED Technology provides confidence and safety by simplifying the protection of high-volume, commercial cooking environments. Its thoughtfully designed functions keep kitchens running efficiently while providing 24/7 protection.

The system is ideally suited for use in catering facilities, cafeterias, casual and fine dining, fast food chains, food courts, hotels and casinos, sports complexes and stadiums and other multi-kitchen facilities.

| Product Name | Download |

|---|---|

| ANSUL® RED Technology | Datasheet |

| Mechanical Sealing Adaptors | Datasheet |

ANSUL SPILL Control Products

Chemical spills happen and can immediately become hazardous waste situations. The SPILL-X product line of free-flowing treatment agents provides a quick, safe and cost-effective alternative spill control method. SPILL-X agents are specifically formulated to treat acid, caustic, solvent and formaldehyde spills by neutralizing, solidifying and/or adsorbing.

Four agents are formulated for various needs, including SPILL-X-A for mineral and organic acid spills; SPILL-X-C for caustic and organic base spills; SPILL-X-S for common hydrocarbon solvents and fuel spills; and SPILL-X-FP for formaldehyde spills. Disposal of spill waste material must meet local, state, and federal regulations.

| Product Name | Download |

|---|---|

| SPILL-X-S Solvent Adsorbent | Datasheet |

| SPILL-X-A Acid Neutralizing/Solidifying | Datasheet |

| SPILL-X-FP Formaldehyde Polymerizer | Datasheet |

| SPILL-X-C Caustic Neutralizing/Solidifying | Datasheet |

The SPILL-X Treatment Kit has been developed to economically treat small spills of many mineral and organic acids, caustics, formaldehyde, and organic solvents or fuels that may occur in laboratories or other work areas where chemicals are used.

The treatment kit provides easy access to the proper spill control agent for a particular chemical spill. Six easy to handle polypropylene containers allow for either a pouring-type application of agent or a shaker-type application, depending on the nature of the spilled chemical. Each container treats up to a 1/2 gal (1.9 L) spill, or approximately 15 to 20 ft2 (1.4 to 1.9 m2).

| Product Name | Download Link |

|---|---|

| SPILL-X Treatment Kit | Datasheet |

Chemical spills can quickly become hazardous waste situations. ANSUL’s SPILL-X products treat spills and can be applied by means of various application options, including the rugged and easy-to-use SPILL-GUN Applicators. These versatile applicators can be recharged in the field. They apply a SPILL-X free-flowing, dry chemical agent from a distance of 10 to 12 ft (3.0 to 3.7 m) and can treat up to a 3 gal (11.4 L) spill, or 100 ft2 (9.3 m2). Their application is for use when spills flow underneath equipment and other hard to reach places.

The R-102 system discharges ANSULEX Liquid Fire Suppressant, which quickly knocks down flames and cools hot surfaces, while generating a tough vapor securing blanket that helps prevent reflash. The R-102 system is designed to protect areas associated with ventilating equipment, including hoods, ducts, plenums, and filters. It also protects auxiliary grease extraction equipment and cooking equipment such as various types of fryers, griddles, range tops, broilers, char-broilers, and woks.

| Product Name | Download Link |

|---|---|

| SC-30 SPILL-GUN applicator | Datasheet |