FAIRCHILD INDUSTRIAL PRODUCTS COMPANY

Fairchild Industrial Products Company manufactures precision, high quality pneumatic and electro-pneumatic industrial control components for leading manufacturers. For more than 50 years, we’ve designed and manufactured one of the largest varieties of precision pneumatic and electro-pneumatic control devices available for process, machine tool, robotic, OEM and other applications. We also offer reliable power transmissions and repair services under our Specon product line.

Fairchild is ISO 9001 approved and authorized to display the CE mark on our electro-pneumatic products. Many of our electro-pneumatic products are also approved for intrinsically safe, explosion-proof and NEMA 4X (IP65) ratings by FM, CSA, ATEX and SAA.

High Pressure Regulators

The Fairchild High Pressure Regulator is for applications involving high supply pressures of up to 6000 psig. With stainless steel construction and a variety of seat materials the High Pressure Regulator can be tailored to applications using gas or liquid media at temperatures of up to 500 degrees Fahrenheit.

Rotork Fairchild's all new PAX1 Series Linear Actuator can be used alone or it can be paired with a variety of Fairchild time proven pressure regulators, enabling remote control of the pneumatic pressure. Power is provided by 11-26 VDC and position is controlled by a 4-20mA signal or pulse clockwise or counterclockwise. The actuator is designed to lock in last place if power or signal are lost. The PAX1 is ideal when precise position control is required, and it has an optional analog feedback that transmits current position to the operator through an 4 to 20 mA Analog Feedback Signal. Adjustable motor speeds, customer set position limits and alarms are standard features.

download datasheet

Rotork Fairchild’s High Pressure Hydraulic - Pressure Reducing Regulator is suitable for 10,000 psig / 690 bar inlet and outlet hydraulic and pneumatic applications. Tapped exhaust port allows for convenient capture of vented media. Age hardened stainless steel allow seat (MP35N) provides a unique combination of ultra high strength, toughness and outstanding corrosion resistance. Zirconia oxide ceramic ball provides high strength and excellent wear resistance to provide reliable, long-lasting unit even the most harsh applications.

download datasheet

The Fairchild HPP pressure regulator will handle a 6000 psi, 414 BAR, maximum supply pressure and offers four (3) output pressure ranges from 0-1000 psi, 0-68.9 BAR, 0-6,890 kPa, up to 0-3000 psi, 0-206.8 BAR, 0-20,680 kPa. The HPP high pressure regulator also offers a supply valve Cv of 0.06. The Rotork Fairchild HPD incorporates a new patented valve and valve seat to prevent leakage, which commonly occurs with high supply pressures.

download datasheet

The Rotork Fairchild HPD pressure regulator will handle a 6000 psi, 414 BAR, maximum supply pressure and offers five (5) output pressure ranges from 0-25 psi, 0-1.7 BAR, 0-170 kPa, up to 5-500 psi, 0.35-35 BAR, 35-3500 kPa. The HPD high pressure regulator also offers a supply valve Cv of 0.06. The HPD high pressure regulator also offers a supply valve Cv of 0.06. The Rotork Fairchild HPD incorporates a new patented valve and valve seat to prevent leakage, which commonly occurs with high supply pressures.

download datasheet

Miniature Pressure Regulators

Model 70 miniature regulator offers high precision in a tiny package. The new Model 72 High Performance Miniature Regulator features an improved design for even better performance, while the Model 50 Polymer regulator excels in lightweight, medical or tough applications.

The Model 70 pneumatic regulator also has an integral vibration damper to provide low noise operation. The Fairchild Model 70 features control sensitivity of 2.5" water column and a supply pressure effect of less than 1% to deliver consistent and reliable precision accuracy to maintain your desired set point regardless of supply pressure changes or conditions. The Model 70 brass pressure regulator will handle a 250 psi, 17 BAR maximum supply pressure and offers five (5) set point pressure ranges from 0-5 psi, 0-3.5 BAR, 0-35 kPa up to 2-100 psi, 0.1-7 BAR, 15-700 kPa. 70220, 70230, 70240, 70250.

download datasheet

The Model 55 pneumatic regulator features control sensitivity of 5" water column to deliver consistent and reliable precision accuracy to maintain your desired set point regardless of supply pressure changes or conditions. The Fairchild Model 50 pressure regulator will handle a 150 psi, 10 BAR maximum supply pressure and offers four (4) set point pressure ranges from 0-10 psi, 0-0.7 BAR, 0-70 kPa up to 2-100 psi, 0.1-7 BAR, 15-700 kPa.

download datasheet

The Fairchild Model 72 pneumatic regulator features control sensitivity of 2" water column and a supply pressure effect of less than 0.5% to deliver consistent and reliable precision accuracy to maintain your desired set point regardless of supply pressure changes or conditions. The Model 72 pressure regulator will handle a 250 psi, 17 BAR maximum supply pressure and offers five (5) set point pressure ranges from 0-5 psi, 0-3.5 BAR, 0-35 kPa up to 2-100 psi, 0.1-7 BAR, 15-700 kPa.

download datasheet

Models PL-5 and PLT-8 Panel Loading Stations maintain and monitor output pressure for pneumatic instrumentation. The PL-5 includes a regulator (Model 10, Model 30, Model 64/65A, or Model 81) and a standard pressure gage that allows operator to set and read pressure at the panel. The PLT-8 includes a regulator (Model 10, Model 30, or Model 64A/65A) and a three-way valve that allows operator to monitor the process in manual or automatic mode. In manual mode, operator can set and read the pressure at the panel. In automatic mode, operator can set the pressure from a remote location and read the pressure at the panel.

download datasheet

High Precision Pressure Regulators

The Fairchild Models 10 and 81 are ideal for general precision pressure regulator applications, while the compact Models 30 and 80 offer high precision in a small package. The Model 100 high flow regulator, the 1000 no bleed pressure regulator, the 4000A no bleed high flow regulator and the Model 4100A Low Pressure regulator also offer high precision control.

The Fairchild Model 10BP will handle a 500 psi, 34 BAR, maximum system pressure and offers nine (9) setpoint pressure ranges from 0-2 psi, 0-0.15 BAR, 0-15 kPa, up to 5-400 psi, 0.3-28 BAR, 35-2800 kPa. The Fairchild Model 10BP back pressure regulator offers 40 SCFM, 68m3/hr flow capacity.

download datasheet

The Fairchild Model 10 pressure regulator will handle a 500 psi, 34 BAR, maximum supply pressure and offers nine (9) output pressure ranges from 0-2 psi, 0-0.15 BAR, 0-15 kPa, up to 5-400 psi, 0.3-28 BAR, 35-2800 kPa. The Model 10 precision regulator offers 40 SCFM, 68 m3/hr flow capacity. Typical Part Numbers are 10212, 10222, 10232, 10242, 10252, 10262, 10272, 10282, 10292, 10233, 10243, 10253, 10263, 10273, 10283, 10293

download datasheet

The Fairchild Model 30 precision regulator will handle a 250 psi, 17 BAR maximum supply pressure and offers five (5) output pressure ranges from 0-2 psi, 0-0.15 BAR, 0-15 kPa up to 2-100 psi, 0.1-7 BAR, 15-700 kPa. 30222, 30232, 30242, 30252, 30223, 30233, 30243, 30253.

download datasheet

The Fairchild Model 81 pneumatic regulator will handle a 250 psi, 17 BAR maximum supply pressure and offers five (5)output pressure ranges from 0-20 psi, 0-1.5 BAR, 0-150 kPa up to 1-100 psi, 0.05-7 BAR, 7-700 kPa. The Model 81 precision regulator has a flow capacity of 50 SCFM, 136 m3/hr.

download datasheet

The Fairchild Model 80 precision regulator will handle a 250 psi, 17 BAR maximum supply pressure and offers three (3) output pressure ranges from 0-20 psi, 0-1.5 BAR, 0-150 kPa up to 1-100 psi, 0.05-7 BAR, 7-700 kPa.

download datasheet

The Fairchild Model 1000 pressure regulator will handle a 250 psi, 17 BAR maximum supply pressure and offers four (4) output pressure ranges from 0.5-10 psi, 0.03-0.7 BAR, 3-70 kPa up to 2-150 psi, 0.14-10 BAR, 14-1000 kPa. The Model 1000 has a flow capacity of up to 50 SCFM, 85 m3/hr.

download datasheet

The Fairchild Model 4000A pressure regulator will handle a 250 psi, 17 BAR maximum supply pressure and offers five (5) output pressure ranges from 0.5-10 psi, 0.03-0.7 BAR, 3-70 kPa up to 5-250 psi, 0.35-17 BAR, 35-1700 kPa. The Model 4000A has a flow capacity of up to 150 SCFM, 255 m3/hr.

download datasheet

The Fairchild Model 100 pressure regulator will handle a 250 psi, 17 BAR maximum supply pressure and offers five (5) output pressure ranges from 0-10 psi, 0-0.7 BAR, 0-70 kPa up to 2-150 psi, 0.14-10 BAR, 14-1000 kPa. The Model 100 has a flow capacity of 1500 SCFM, 2550 m3/hr.

download datasheet

The Fairchild Model 4100A high precision pressure regulator will handle a 150 psi, 10 BAR maximum supply pressure and offers four (4) output pressure ranges from 0-0.7 psi, 0-0.048 BAR, 0-4.8 kPa up to 0-5 psi, 0-0.35 BAR, 0-35 kPa. The Model 4100A has a flow capacity of 30 SCFM, 51m3/hr.

download datasheet

The Fairchild Model 11 high precision pressure regulator will handle a 150 psi, 10 BAR maximum supply pressure and offers five (5) output pressure ranges from 0-0.5 psi, 0-0.034 BAR, 0-3.4 kPa up to 0-12 psi, 0-0.83 BAR, 0-83 kPa. The Model 11 has a flow capacity of 27 SCFM, 40.7 m3/hr.

download datasheet

Back Pressure Regulators

Back Pressure Regulators work well where applications require high precision control of back pressure or relief pressures. The Model 10BP offers high precision, as does the compact Model 30BP. In addition, the Model 50BP Polymer, Model 66BP Stainless Steel, and Model 4000ABP high flow back pressure regulators are designed by Fairchild for tough applications.

The Fairchild Model 10BP will handle a 500 psi, 34 BAR, maximum system pressure and offers nine (9) setpoint pressure ranges from 0-2 psi, 0-0.15 BAR, 0-15 kPa, up to 5-400 psi, 0.3-28 BAR, 35-2800 kPa. The Fairchild Model 10BP back pressure regulator offers 40 SCFM, 68m3/hr flow capacity.

download datasheet

The Model 30BP pneumatic regulator an excellent choice for a wide range of precision applications including: Precise Control of Paper Machinery Felt Guides, Supply of a Precise Repeatable Signal to a Pneumatic Clutch, or Control of Cylinder Pressure. The Fairchild Model 30BP back pressure regulator will handle a 250 psi, 17 BAR maximum system pressure and offers five (5) set point pressure ranges from 0-2 psi, 0-0.15 BAR, 0-15 kPa up to 2-100 psi, 0.1-7 BAR, 15-700 kPa.

download datasheet

The Fairchild Model 4000ABP back pressure regulator will handle a 250 psi, 17 BAR maximum system pressure and offers four (4) set point pressure ranges from 0.5-10 psi, 0.03-0.7 BAR, 3-70 kPa up to 2-150 psi, 0.1-10 BAR, 15-1000 kPa.

download datasheet

he Fairchild Model 66BP back pressure regulator will handle a 150 psi, 10 BAR maximum system pressure and offers five (5) set point pressure ranges from 0-10 psi, 0-0.7 BAR, 0-70 kPa up to 2-150 psi, 0.15-10 BAR, 15-1000 kPa.

download datasheet

Filter/ Service and Specialty Pressure Regulators

High flow and good filtration are critically important and the Fairchild Model 63 and slightly wider Model 65 filter service pressure regulators offer world class performance on both counts. In addition to standard products, Specialty Pressure Regulators, such as the Model 2400 standard, low, and high pressure series Motorized Regulators were developed by Fairchild for fast and convenient actuation and automation.

Take full advantage of compressed gases on pneumatic systems. The gas must be adequately prepared. Fairchild's FR preparation package provides the clean, dry air essential for optimum performance of pneumatic systems. With their modular construction, the FR units provide compact efficiency, high flow, and superior 5 micron filtration.

download datasheet

The Fairchild Model 63N NACE will handle 300 psi, 20 BAR, maximum supply pressure and offers three (3) output pressure ranges from 0.5-30 psi, 0.03-2 BAR, 3-200 kPa, up to 2-120 psi, 0.14-8 BAR, 14-800 kPa and up to 25 SCFM, 42.5 m3/hr flow capacity. This model also has Canadian Registration (CRN) for all territories and provinces.

download datasheet

The Fairchild Model 63N NACE will handle 300 psi, 20 BAR, maximum supply pressure and offers three (3) output pressure ranges from 0.5-30 psi, 0.03-2 BAR, 3-200 kPa, up to 2-120 psi, 0.14-8 BAR, 14-800 kPa and up to 25 SCFM, 42.5 m3/hr flow capacity. This model also has a Canadian Registration (CRN) for all territories and provinces.

Take full advantage of compressed gases in pneumatic systems. The gas must be adequately prepared. Fairchild's new Particulate Filters provide the clean, dry, lubricated air essential for optimum performance of pneumatic systems. With their modular construction, the particulate filters provides compact efficiency, high flow, and superior 5 micron filtration.

download datasheet

Fairchild's new FR preparation package provides the clean, dry air essential for optimum performance of pneumatic systems. With their modular construction, the FR unit provides compact efficiency, high flow, and superior 5 micron filtration. Output pressures up to 125 psig and flow to 175 SCFM.

download datasheet

he directly-controlled Model 67 stainless steel regulator precisely controls fuel pressures in ranges from minus 6 to 60 psi. The large diaphragm actuator with directlycontrolled valve gives excellent response characteristics with very low hysteresis. High precision control is achieved by its forcebalanced valve, with a newly developed patented smooth running seal system. Specially developed for the high precision and reliability requirements of modern engine test equipment, the M67 is suitable for all fuels such as gasoline, diesel, biodiesel (RME), aviation fuel, methanol,ethanol, petrol mixtures E5 to E100 and diesel mixtures B5 to B100.

download datasheet

Fairchild's new Coalescing Filters provide the clean, dry, lubricated air essential for optimum performance of pneumatic systems. With their modular construction, the coalescing filters provides compact efficiency, high flow, and superior 0.5, 0.01, or 0.003 micron filtration.

download datasheet

The Fairchild Model 63 will handle a 300 psi, 20 BAR, maximum supply pressure and offers three (3) output pressure ranges from 0.5-30 psi, 0.03-2 BAR, 3-200 kPa, up to 2-120 psi, 0.14-8 BAR, 14-800 kPa. The Fairchild Model 63 pressure regulator offers up to 25 SCFM, 42.5 m3/hr flow capacity.

download datasheet

The Fairchild Automatic Drain Filter Series is designed for use in systems that require clean, oil-free air. This series consists of a particulate filter and two coalescing filters with automatic drains. You can easily replace all filter elements. Automatic Drain Filters are highly effective in removing oil and liquid-borne particulate matter. These units are recommended for use when clean air or inert gas environments are required in laboratory air, process control, instrument and compressed air systems.

download datasheet

The Fairchild Model 66 pressure regulator will handle a 500 psi, 35 BAR maximum supply pressure and offers five (5) set point pressure ranges from 0-10 psi, 0-0.7 BAR, 0-70 kPa up to 2-150 psi, 0.15-10 BAR, 15-1000 kPa.

download datasheet

The Fairchild MP2400 motorized regulator line will handle a 500 psi, 35 BAR maximum supply pressure and offers eleven (11) different set point pressure ranges from Vacuum-10 psi, vacuum-0.7 BAR, vacuum-70 kPa up to 2-100 psi, 0.15-7 BAR, 15-700 kPa.

download datasheet

The Fairchild Model 65 pneumatic regulator will handle a 300 psi, 20 BAR, maximum supply pressure and offers three (3) output pressure ranges from 0.5-30 psi, 0.03-2 BAR, 3-200 kPa, up to 2-120 psi, 0.14-8 BAR, 14-800 kPa. The Fairchild Model 65 pressure regulator offers up to 25 SCFM, 42.5 m3/hr flow capacity.

download datasheet

The Model 2400 M/P Low Pressure Converter is also a motorized regulator, however, this unit uses a larger diaphragm regulator as its pressure control device to facilitate high accuracy set point control. The pneumatic control circuit is isolated from any explosive environment by enclosing the motor and associated electronics an explosion-proof housing. The large diaphragm regulator attaches to the motor housing and provides precision control in three (3) available pressure ranges, from 0-20 in water column, up to 0-5 psi. In these configurations, the MP2400Low Pressure motorized regulator will handle a supply pressure up to 150 psi, 10BAR, 1000 kPa.

download datasheet

Take full advantage of your compressed gas system by adding a modular ball shutoff valve. A ball shutoff valve is essential for quick turn around of maintenance and replacement of in-line system components. Save time and money onn the cost of repairs of system components with Fairchild's new modular ball valves. The lockout feature of Fairchild's new ball valves provide a sage and more fluid work environment. Fairchild's new modular ball shutoff valves are rugged with extreme high flow capacity and quality construction. Port sizes from 1/4" to 3/4" with flow capacities ranging from 42 SCFM to 678 SCFM. Also available are a full line of brackets and gauge accessories to complete your air preparation package.

download datasheet

Models MPL-70 and MPLT-70 Mini-panel Loading Stations transmit and monitor a pressure signal for pneumatic instrumentation. These loading stations are ideally suited for applications with limited space. The Model MPL-70 includes a Model 70B Pneumatic Subminiature Regulator and a mini-strip gage to set and read pressure at the panel. The MPLT-70, with the Transfer Function, includes a Model 70B Pneumatic Subminiature Regulator, an automatic or manual switch, and an additional mini-strip gage to monitor the process in automatic mode or change pressure settings in manual mode. Turn the adjusting knob in the loading station panel in a clockwise direction to increase output pressure or in a counterclockwise direction to decrease output pressure.

download datasheet

The Fairchild line of 1 1/2", 2", and 3 1/2" diameter Gages are designed for general use in applications that use gas or liquid medium that is compatible with the brass and brass alloy components in the gage. Mini Strip Gages are designed for use in small panel mount applications. Both gage styles include a receiver gage configuration designed for the pneumatic transmission of process variables.

download datasheet

Vacuum Regulators

Vacuum regulators cover all applications from full vacuum in the Model 17 Vacuum Regulator and Model 18 Vacuum Relief Regulator to those in low pressure and lighter vacuum, handled by the Model 16 Vacuum Regulator and the Model 1600 High Flow Vacuum Regulator.

The Fairchild Model 16 will handle a 250 psi, 17 BAR, maximum supply pressure and offers five (5) output pressure ranges from Vacuum-2 psi, Vacuum-0.15 BAR, Vacuum-15 kPa, up to Vacuum-150 psi, Vacuum-10 BAR, Vacuum-1000 kPa. The Fairchild Model 16 pressure regulator offers up to 40 SCFM, 65 m3/hr positive flow capacity.

download datasheet

The Fairchild Model 1600A will handle a 250 psi, 17 BAR, maximum supply pressure and offers three (3) output pressure ranges from Vacuum-10 psi, Vacuum-0.7 BAR, Vacuum-70 kPa, up to Vacuum-150 psi, Vacuum-10 BAR, Vacuum-1000 kPa. The Fairchild Model 1600A pressure regulator offers up to 28 SCFM, 48 m3/hr vacuum flow capacity.

download datasheet

The Fairchild Model 17 will handle a 40 in Hg, 762 Torr, 102 kPa maximum supply vacuum and offers three (3) output vacuum ranges from 0-5 in Hg, 0-127 Torr, 0-17 kPa, up to 0-30 in Hg, 0-762 Torr, 0-102 kPa. The Fairchild Model 17 pneumatic vacuum regulator offers up to 12 SCFM, 20.4 m3/hr flow capacity.

download datasheet

The Fairchild Model 18 will handle a 30 in Hg, 762 Torr, 102 kPa maximum supply vacuum and offers three (3) relief vacuum ranges from 4 in Hg, 140 mBar, 14 kPa, up to 30 in Hg, 1000 mBar, 100 kPa. The Fairchild Model 18 pneumatic vacuum relief regulator offers up to 8 SCFM, 68 m3/hr flow capacity.

download datasheet

Pneumatic Volume Boosters

Pneumatic volume boosters feature high flow capacity and fast response. A wide range of signal to output pressure ratios, pipe sizes and options are available in Fairchild’s pilot operated regulator booster products with a Cv of 1 up to a Cv of 18, with flow capacities of 45 SCFM, 76.5 m3/hr up to 1500 SCFM, 2550 m3/hr.

The Model 2000 Pneumatic Volume Booster converts a low flow signal to a high flow output. It is ideally suited for a variety of applications including the operation of air systems that require rapid valve or cylinder action. With its balanced supply valve and aspirator tube, the M2000 booster will maintain setpoint while delivering a strong boost of volume. In addition, its no bleed soft seat design minimizes air consumption of the system. As a pilot operated regulator design, the M2000 handles up to 250 psig, [17.0 BAR], (1700 kPa) supply pressure. The M2000 provides a flow capacity of 40 SCFM (68 m3/HR), which results in a Cv factor of just less than 1.0 in forward flow mode.

download datasheet

The Model 20BP is a smaller Back Pressure Pneumatic Booster designed for automated or remote controlling of the back pressure or relief operation typically found in tank systems and other pressurized systems. In its pilot operated design, the M20BP will operate from a signal pressure of up to 150 psig [10.0 BAR] (1000kPa) and handles up 250 psig, [17.0 BAR], (1700 kPa) system pressure. The Fairchild Model 20BP Back Pressure Booster provides a flow capacity of 45 SCFM (76.5 m3/HR), which equates to a Cv factor of approximately 1.0.

download datasheet

The Model 20 Volume Booster is a smaller pneumatic device capable of high flow and exhaust capacity. This device uses a force balance system to control the movement of the supply and exhaust valves. As a pilot operated regulator design, the M20 handles up to 150 psig, [10.0 BAR], (1000 kPa) supply pressure and has ten available ratios to cover a wide range of applications. The M20 Booster provides a flow capacity of 45 SCFM (76.5 m3/HR), which equates to a Cv factor of approximately 1.0 in forward mode. Typical Part Numbers are 20812, 20822, 20832, 20842, 20852, 20862, 20813, 20823, 20833, 20843, 20853, 20863.

download datasheet

Fairchild’s M4500ABP is a High Flow Back Pressure Booster designed for automated or remote controlling of the back pressure or relief operation typically found in tank systems and other pressurized systems. In its pilot operated design, the M4500ABP will operate from a signal pressure of up to 150 psig [10.0 BAR] (1000kPa) and handles up 250 psig, [17.0 BAR], (1700 kPa) system pressure. The Fairchild Model 4500ABP Back Pressure Booster provides a flow capacity of 150 SCFM (255 m3/HR), which equates to a Cv factor of approximately 3.0.

download datasheet

Fairchild's Model 4500 Pneumatic Volume Boosters are popular due to their rugged design and high flow capacity in an economical package. In its pilot operated regulator design, the M4500 handles up 250 psig, [17.0 BAR], (1700 kPa) supply pressure and has five available signal to output ratios to meet most control element requirements. The 4500 Booster provides a flow capacity of 150 SCFM (255 m3/HR), which equates to a Cv factor of approximately 3.0 in both forward and exhaust modes. 4514A, 4524A, 4534A, 4544A, 4554A, 4516A, 4526A, 4536A, 4546A, 4556A.

download datasheet

Fairchild’s M4800A is a High Flow Pneumatic Volume Booster specifically designed for Valve and valve actuation systems. With its Cv of 9 in both forward and exhaust modes, this pilot operated booster provides fast response and accurate control for valve actuation. In addition, the M4800A has an integral bypass valve, for optimum tuning and adjustment, even while in operation, to obtain maximum performance on opening and closing times with minimal overshoot or oscillation. In its pilot operated regulator design, the M4800A handles up 250 psig, [17.0 BAR], (1700 kPa) supply pressure and delivers an output pressure up to 150 psig [10.0 BAR] (1000kPa). The Fairchild Model 4800A Booster provides a flow capacity of 500 SCFM (850 m3/HR), which equates to a Cv factor of approximately 9 in both forward and exhaust modes.

download datasheet

Fairchild’s M4900A is a High Flow Pneumatic Volume Booster designed for high precision applications. With its Cv of 9 in both forward and exhaust modes, this pilot operated booster provides fast response, very low deadband and high precision control. In its pilot operated regulator design, the M4900A handles up 250 psig, [17.0 BAR], (1700 kPa) supply pressure and delivers an output pressure up to 150 psig [10.0 BAR] (1000kPa). The Fairchild Model 4900A Booster provides a flow capacity of 500 SCFM (850 m3/HR), which equates to a Cv factor of approximately 9 in both forward and exhaust modes.

download datasheet

Based on the Model 200 valve body, the Model 200XLR Volume Booster couples two identical units to obtain ultra high flow capacity in both forward and exhaust modes. As a pilot operated regulator design, the M200 handles up to 250 psig, [17.0 BAR], (1700 kPa) supply pressure and provides a flow Ultra high capacity of 1800 SCFM (3058 m3/HR), which equates to a Cv factor of approximately 18 in both forward and exhaust flow modes.

download datasheet

The Model 200 Pneumatic Volume Booster reproduces a pneumatic signal in a 1:1 ratio. It is ideally suited for systems that require input isolation or increased forward flow capacity. This device uses a force balance system to control the movement of the supply and exhaust valves. As a pilot operated regulator design, the M200 handles up to 250 psig, [17.0 BAR], (1700 kPa) supply pressure and provides a flow Ultra high Flow capacity of 1800 SCFM (3058 m3/HR), which equates to a Cv factor of approximately 18 in forward flow mode.

download datasheet

Fairchild Relays

Fairchild extensive line of pneumatic relays serves a multitude of control applications: positive biasing relays, positive and negative biasing relays, infinitely adjustable ratio relays, reversing relays, averaging and computing relays, high and low pressure selectors, and high and low pressure limiting relays.

Designed for applications that require an output pressure that is the sum of a controlled input signal plus or minus a fixed bias, Fairchild's Model 14 Biasing Pneumatic Relay provides versatility in its ability to provide either positive or negative biasing in a single unit. The output of the Model 14 relay is the sum of the spring bias, set with the Range Screw, plus a pneumatic input signal. (Po = Ps � K); where Po is output pressure, Ps is signal pressure, and K is the combined spring constant.

download datasheet

The Model 85D Multi-Stage Biasing Relay is a precision control combining the sensitivity of a precision pressure regulator with positive biasing capability. This compact, pilot-operated device offers unusually high output capacity with minimal air consumption, while providing excellent protection against supply or output pressure variations. The versatile Model 85D is recommended for use in systems requiring precision pressure maintenance and instrument biasing, in dead end service and instrument panel supply applications. The basic mathematical expression for the Fairchild Model 85D is PO = PS + K where PO is output pressure, PS is signal pressure and K is the spring constant.

download datasheet

The Model 15 Positive Bias Relay is designed for applications that require an output pressure that is the sum of a controlled input signal plus a fixed bias. This pneumatic relay provides an output pressure that represents the input signal pressure plus a preset bias. Mathematically Po = Ps + K where Po is output pressure, Ps is signal pressure and K is the spring constant. This unit, available in several bias range configurations to meet a variety of output requirements, offers excellent sensitivity and high flow capacity in a small volume. The Fairchild Model 15 Pneumatic Biasing Relay is well suited to a variety of control applications, including range shifting, and tension control, and pressure control from a remote location.

download datasheet

The Model 1500 Positive Bias Relay is designed for applications that require an output pressure that is the sum of a controlled input signal plus a fixed bias. This pneumatic relay provides high output flow at an output pressure that represents the input signal pressure plus a preset bias. The output of the relay is the sum of the spring bias, set with the Range Screw, plus a pneumatic input signal. (Po = Ps + K); where Po is output pressure, Ps is signal pressure, and K is the spring constant set by the Range Screw.

download datasheet

The Model 25 Reversing Relay is designed for applications requiring an output that equals a manually preset spring load minus a variable signal pressure. This high quality unit combines excellent sensitivity with unusually high flow capacity. The Model 25 is ideally suited for a variety of precision control applications, including converting direct acting valves to reverse action, controlling opposite acting valves from a single transmitter, and cushioning cylinder loads. The basic mathematical expression for the Model 25 is PO = K - PS where PO is output pressure, PS is signal pressure and K is the spring constant.

download datasheet

The Model 2500A Bias Reversing Relay provides an outlet pressure that decreases in direct proportion to increases in input signal. The input signal that acts on the Diaphragm Assembly opposes the Range Spring force and closes the Supply Valve to decrease output pressure, according to the formula (Po = K - Ps); where Po is output pressure, K is the spring constant, set by the screw, and Ps is signal pressure. The M2500A pneumatic relay delivers this performance at a flow capacity of 150 SCFM (255 m3/HR), to provide fast response and tight control over your application.

download datasheet

The Model 21 Adjustable Ratio pneumatic relay has a signal chamber lever arm, whereby the ratio of output pressure to signal pressure is infinitely adjustable. The adjustment range permits signal amplification of 1:30 or signal reduction of 30:1 by rotation of the ratio adjustment knob which moves the fulcrum. . Output pressure is a function of signal pressure times the ratio of lever arm lengths on either side of the fulcrum. Bias may be introduced by means of the set screws. The Model 21D is available with both input and output adjustable bias. Maximum input bias is 3 psig, with a maximum output bias of 9 psig. The basic mathematical expression for the bias in this relay is Po = (Ps-K1) R+K2, where Po = Output pressure, Ps = Input signal, R = Ratio of setting, K1= Input bias, (-) only, and K2 = Output bias, (+) only.

download datasheet

The Model 22 Pneumatic Computing Relay is a highly versatile control valve designed to perform a number of specialized functions, including averaging, differential, inverting, and totalizing. This high quality unit, which offers up to four inputs as well as positive and negative biasing over a broad range, is available in several configurations to meet most application requirements. The combination of multiple configuration options and accurate response characteristics make the Model 22 the ideal choice in a variety of applications with specific input/output requirements such as override or multi-element control, or as an ON-OFF valve. When used as an ON-OFF valve, the Model 22 may open or close a pneumatic circuit, moving rapidly to a full open or a full closed position when signal pressures deviate from set point. In the full open position, the valve passes full supply pressure without modulation or regulation.

download datasheet

The Model 24 Snap Acting Relay is a highly accurate differential relay with snap-acting switching. The output of the unit will go to supply pressure when the signal is equal to or greater than the setpoint. The signal pressure must fall below the set point to return the output to zero. This pneumatic relay's Near Zero Throttling and Pilot Staging result in true snap-action in your application.

download datasheet

The Model 90 Low Pressure Selector Relay is designed to select the lower of two signal pressures to provide a continuous output pressure to a control device. The Model 90 is recommended for dead end or low flow service in critical applications such as control loops requiring precise, automatic monitoring of signal pressures.

download datasheet

The Model 91 High Pressure Selector Relay is designed to select the higher of two signal pressures, and to provide a continuous output pressure (or pressure range) to a controller. The ability to precisely control pressure switching and pressure monitoring functions make the Model 91 the logical choice in dead end or low flow applications such as precision control loops.

download datasheet

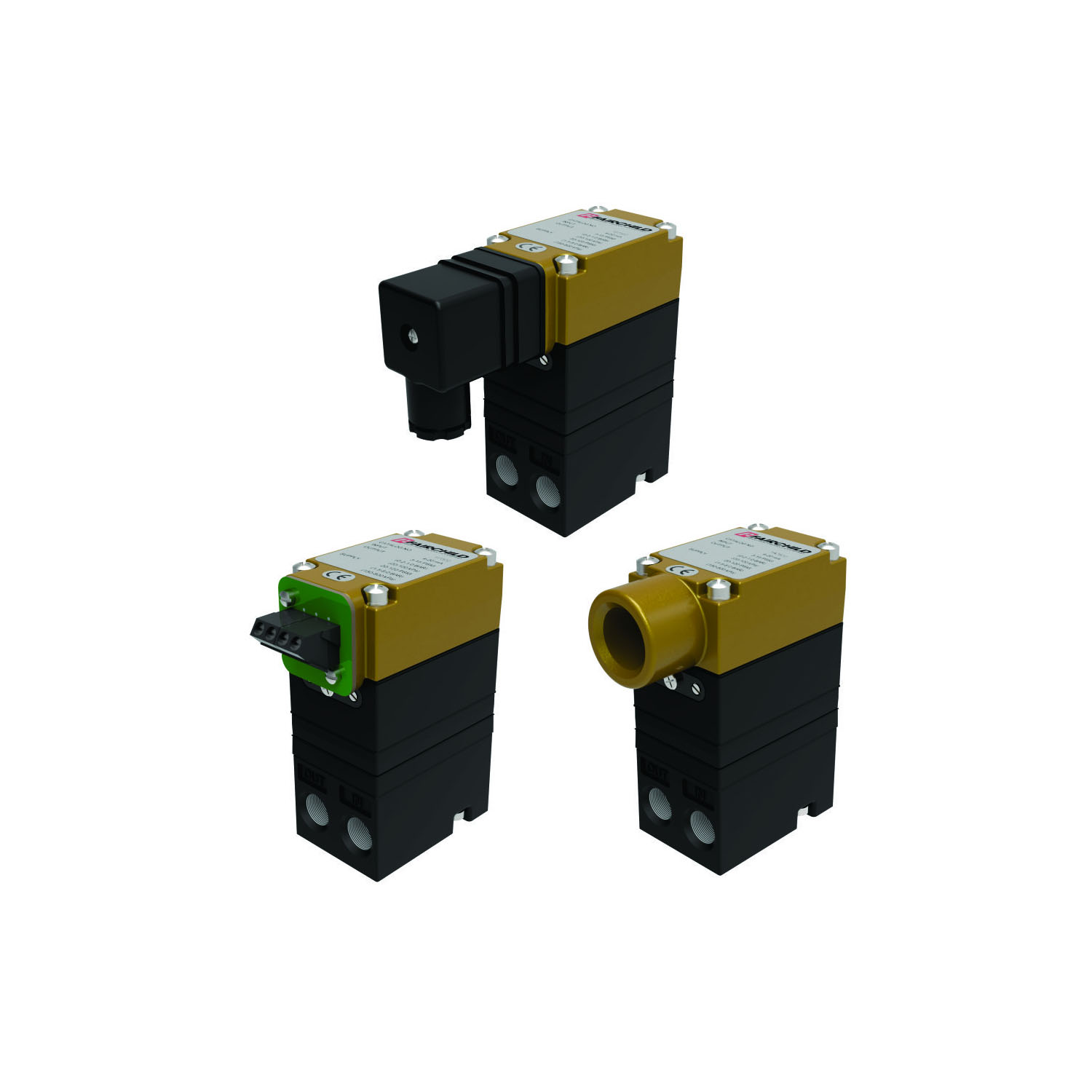

Fairchild Electro-Pneumatic Transducers

Accurate, compact I/P, E/P, D/P & P/I electro-pneumatic transducers with extensive combinations of inputs and outputs carry standard FM, CSA, ATEX or IECEx agency approvals and maintain accuracies up to 0.15%. Fast response transducers, high flow transducers and high accuracy transducers developed by Fairchild feature proportional pressure regulation.

Rotork Fairchild's T5200 Transducer is a Fast Response I/P, E/P Transducer controlled by a 4-20 mA current in a control loop. With its reliable signal conversion and pneumatic circuit sections, the T5200 I/P Transducer provides fast response to input signal changes, resulting in faster loop control and savings in process materials. The Signal Conversion Section (PC Board) accepts a 4-20 mA current from the control loop. This signal current is applied to a coil which creates a magnetic force that moves a Flexure Arm. The Pneumatic Section operates as a force balance system. A Sapphire Ball floats inside a Nozzle and controls the output pressure by exhausting air supplied through an Orifice. This Sapphire Ball acts as a piston exerting a force which is balanced against the force of the Flexure Arm.Its minimal air consumption allows you to use the T5200 in systems where operating gas is expensive. Five available input signal ranges deliver the versatility to meet most process and machine requirements. These available inputs are 1-5 mA, 4-20 mA, 10-50 mA, 1-5 VDC and 1-9 VDC, each with the corresponding output range of 3-15 psig, [0.2-1.0 BAR], (20-100 kPa).

download datasheet

As a Fast Response High Flow I/P, E/P Transducer, the Fairchild T5220 has all the performance you want in a voice coil I/P transducer product, but it also includes a built in booster section to deliver high flow capacity, up to 45 SCFM (76.5 m3/HR) with six available rations to allow pressure multiplication to the output. This feature, along with the adjustable positive and negative bias allows you to custom design your control system for exactly the desired performance. The Signal Conversion Section (PC Board) accepts a DC current or voltage. This signal is applied to a coil which creates a magnetic force that moves a Flexure Arm. The Pneumatic Section operates as a force balance system. A Sapphire Ball floats inside a Nozzle and controls the output pressure by exhausting air supplied through an Orifice. This Sapphire Ball acts as a piston exerting a force which is balanced against the force transferred to the Flexure Arm by the Coil. The Booster Section amplifies the output pressure of the transducer.

download datasheet

When your application requires a very specific control system, look to the T5221 Adjustable Ratio I/P, E/P Transducer. The T5221 Transducer is an electro-pneumatic device that converts a DC current or voltage input signal to a proportional output pressure. This device is made up of four sections, the Signal Conversion Section, the Pneumatic Section, the Ratio Section, and the Booster Section. The Fairchild T5221 I/P transducer has all the response and flow performance features of the T5200 series, with the addition of an Adjustable Gain from the ratio section, which allows this single device to cover most industrial and process control requirements. The output pressure is a function of signal pressure times the ratio of lever arm lengths on either side of the Pivot.

download datasheet

Fairchild's Model T5700 is an electro-pneumatic transducer that converts a current signal to a linear pneumatic output, using a force balance system with a flapper and the nozzle to control the pressure in the intermediate housing. Its low droop under flow conditions allows improved control of downstream pressure. Additionally, the T5700 has high flow and is virtually immune to supply pressure change, which permits use of normal plant air. The T5700's minimal air use in dead end service (.05 SCFM) dramatically reduces air consumption.

download datasheet

The T6000 compact size E/P, I/P pressure transducer is a field reversible unit that provides an output directly or inversely proportional to the input signal. Its six available output pressure ranges and six available input signal ranges meet most process and machine requirements. The T6000 Series is designed for precision applications providing maximum versatility. The modular construction permits any basic unit to be used in the explosion-proof, rack, wall, pipe, panel, DIN rail or 3, 5, 10, or 15 unit manifold configurations and servicing or calibration is quick and easy. An extended range T6000 I/P Transducer is also available, which provides output pressure capability up to 0-120 psi [0-8.0 BAR], (0-800 kPa). The Extended Unit is made up of three sections, the Primary Control Section, the Pneumatic Relay Section, and an additional Pneumatic Relay Section. The additional Relay Section is used to amplify the output pressure.

download datasheet

The TXPD6000 I/P transducer is a field reversible unit that provides an output directly or inversely proportional to the input signal. Its six available output pressure ranges and six available input signal ranges meet most process and machine requirements. The TXPD6000 Series is designed for precision applications providing maximum versatility. In this explosion proof NEMA 4X configuration, the TXPD6000 is approved by FM, CSA and ATEX and ready for your installation in hazardous duty.

download datasheet

Uniquely designed by Fairchild, the T6100 "Lock in Last Place" I/P pressure transducer provides flexibility, reliability and safety in applications requiring protection from signal failures to critical control system instruments. Its simple yet effective voice coil actuation now Locks in "Last Position" to accurately capture the setpoint with extremely low drift after a power loss permits the T6100 to maintain set point. The unit's IP65 rating allows you to handle moist applications with ease. Design of the T6100 relies on a proprietary integrated solenoid valve module interposed between the flapper-nozzle pilot and the booster section.

download datasheet

The T7500 series low pressure transducer converts DC electronic input signal to a proportional low pressure pneumatic output. The transducer employs electronic closed loop feedback in conjunction with a piezoceramic actuator flapper nozzle system in the pilot stage to control the signal pressure of an integral pneumatic volume booster. The volume booster employs a highly sensitive control diaphragm and main valve to accurately control the flow of air to the downstream system in response to the pressure received from the pilot stage. The electronic closed loop feedback senses the output pressure of the volume booster directly to affect the ultimate in accurate pressure control.

download datasheet

High performance at economical process is available from the Fairchild T7800 series of piezo-ceramic actuated I/P transducer. These units offer state of the art accuracy up to 0.15% FS. The disc actuation mechanism provides a product that is totally impervious to shock, vibration and positional orientation. In the Extended Range units, an additional Relay Section amplifies the output pressure to obtain up to 0-120 psi [0-8.0 BAR], (0-800 kPa) output. The T7800 series is approved for Intrinsic Safety and Non-Incendive use carries FM, CSA, ATEX and IECEx approvals.

download datasheet

Designed for use in hazardous environments, the Fairchild TXI7800 series product is an explosion proof I/P pressure transducer. It operates under the same principles as the T7800 product; however the TXI series includes NEMA 4X explosion proof construction. Our design isolates the electronics chamber from the pneumatic section, thereby creating a safer and longer service life product, especially for applications handling natural gas. In the Extended Range units, the TXI7800 series will also deliver up to 0-120 psi [0-8.0 BAR], (0-800 kPa) output. The TXI7800 series is approved for hazardous use and carries FM. CSA, ATEX and IECEx approvals.

download datasheet

Designed for use in hazardous environments, the Fairchild TXI7800 series product is an explosion proof I/P pressure transducer. It operates under the same principles as the T7800 product; however the TXI series includes NEMA 4X explosion proof construction. Our design isolates the electronics chamber from the pneumatic section, thereby creating a safer and longer service life product, especially for applications handling natural gas. In the Extended Range units, the TXI7800 series will also deliver up to 0-120 psi [0-8.0 BAR], (0-800 kPa) output. The TXI7800 series is approved for hazardous use and carries FM. CSA, ATEX and IECEx approvals.

download datasheet

Fairchild's TXI7850 I/P Pressure Transducer operates under the same basic principles as the TXI7800, yet improves upon the design. By encapsulating and otherwise protecting the critical components, Fairchild designed the Explosion proof TXI7850 I/P Pressure Transducer to be highly resistant to moisture within the supply air lines. Available in both standard and extended range configurations, the TXI7850 delivers vibration, shock and moisture resistance in output pressures up to 0-120 psi [0-8.0 BAR], (0-800 kPa). It carries full Agency Approvals, including FM, CSA and ATEX certifications.

download datasheet

Fairchild's TXI7850 I/P Pressure Transducer operates under the same basic principles as the TXI7800, yet improves upon the design. By encapsulating and otherwise protecting the critical components, Fairchild designed the Explosion proof TXI7850 I/P Pressure Transducer to be highly resistant to moisture within the supply air lines. Available in both standard and extended range configurations, the TXI7850 delivers vibration, shock and moisture resistance in output pressures up to 0-120 psi [0-8.0 BAR], (0-800 kPa). It carries full Agency Approvals, including FM, CSA and ATEX certifications.

download datasheet

Fairchild's TXI7850 operates under the same basic principles as the TXI7800, yet improves upon the design. By encapsulating and otherwise protecting the critical components, Fairchild designed the Explosion proof TXI7850 I/P transducer to be highly resistant to moisture within the supply air lines. Available in both standard and extended range configurations, the TXI7850 delivers vibration, shock and moisture resistance in output pressures up to 0-120 psi [0-8.0 BAR], (0-800 kPa). It carries full Agency Approvals, including FM, CSA and ATEX certifications. I/P Pressure Transducer, I/P Pressure converter.

download datasheet

T8000 P/I Transducer Series is a miniature two wire pressure device that converts a pneumatic input signal to a linearly proportional output current. It is field reversible and offers output choices of 4-20 mA or 10-50 mA. The T8000 Series is designed for precision applications providing maximum versatility. The modular construction permits any basic unit to be used in the explosion-proof, rack, wall, pipe, panel, DIN rail or 3, 5, 10, or 15 unit manifold configurations. Servicing or calibration is quick and easy. The Zero and Span adjustments are easily accessible from the front of the unit. The T8000 Series may be configured as a Single or Dual Channel Unit. The Dual Channel Unit consists of two PC Boards that are enclosed within the same housing and function independently of each other. This unit may be offered in any one of the seven standard input pressure signals or in any combination.

download datasheet

The Fairchild T9000 Series Electro-Pneumatic Pressure Controller has a closed-loop, integrated, microprocessor control system that regulates outlet pressure. The Model T9000 controls pressure in proportion to an analog electrical input signal. An internal feedback sensor monitors output pressure to achieve high accuracy. You can control the output from the Model T9000 using the keypad or from an analog control signal. You can control the output from the Model T9000D using the keypad and through DeviceNet™ Communication network. With its integral booster sections, the T9000 series of I/P pressure controllers delivers high accuracy at flow capacities of 1 SCFM in the T9000, 90 SCFM in the T9020, 110 SCFM in the T9040, 220 SCFM in the T9060, and 700 SCFM in the T9080.

download datasheet

Manifold and Rack Kits

Manifold Kits for the T6000, T7800 and T7950 Series Transducers are available for mounting 3, 5, 10 or 15 transducer units. These manifolds have a common supply port to all the transducers. Supply port connections are provided on the end and rear of the manifold. Outlet ports are located on the rear and bottom of the manifold. All T6000, T7800 and T8000 Rack Kits utilize a 10 unit manifold and include additional hardware to permit installation in a standard 19″ Rack.

All T6000, T7800 and T8000 Rack Kits utilize a 10 unit manifold described in the above manifold kits. The rack kit includes additional hardware to permit installation in a standard 19" Rack. It is suggested that transducers used with rack kits include the "R" option. This option faces the electrical terminal block connector to the rear of the transducer permitting connections to the transducer to be made from the rear of the rack.

download datasheet

The Manifold Kits for the T6000, T7800 and T7950 Series Transducers are available for mounting 3, 5, 10 or 15 transducer units. These manifolds have a common supply port to all the transducers. Internal check valves in the inlet and outlet ports permit the installation and removal of individual transducers without affecting other units on the manifold. Supply port connections are provided on the end and rear of the manifold. Outlet ports are located on the rear and bottom of the manifold. Mounting brackets for flush or extended mounting from the back wall are available. These options allow the user to select the combination of supply ports, outlet ports and mounting configurations to maximize usage of available space.

download datasheet

Manifold kits for the T8000 Series Transducers are also available for mounting 3, 5, 10 or 15 transducer units. All input ports on the manifold have internal check valves to seal off the input signal(s) if a transducer is removed from the manifold. Since each housing may contain two individual P/I transducers, the quantity of P/I's on the manifold has the capability of doubling. Rear and bottom input port connections and flush or extended mounting brackets allow the user to configure the manifold to maximize the use of available space.

download datasheet

Legacy Products (Obsolete)

The Fairchild T7900 Series Electro-Pneumatic Transducers have a closed-loop, integrated, microprocessor control system that regulates outlet pressure. The Model T7900 controls pressure in proportion to an analog electrical input signal. An internal feedback sensor monitors output pressure to achieve high accuracy. You can control the output from the Model T7900 using the keypad or from an analog control signal. You can control the output from the Model T7900D using the keypad and through DeviceNet™ Communication network. With its integral booster section, the T7900 delivers high accuracy at its high flow capacity of 100 SCFM (170 m3/HR).

download datasheet

Fairchild's new T1750 I/P, E/P pressure transducer delivers high performance in terns of its high accuracy, high pressure, high flow and fast response. It operates with the same pinpoint accuracy from 15 psi [1BAR], (150 kPa) output all the way up to 750 psi [50 BAR] (5 MPa) output. This unit moves tremendous air volume, as its 1000 SCFM (1700 m3/HR) flow capacity is second to none. When you need fast response you can rely on the T1750 response time of less than 15 ms. The Model T1750 Transducers have a closed-loop, integrated, microprocessor control system that regulates outlet pressure.

download datasheet

TXI8000 P/I Transducer Series is a miniature two wire pressure device that converts a pneumatic input signal to a linearly proportional output current. It is field reversible and offers output choices of 4-20 mA or 10-50 mA. The TXI8000 Series is designed for precision applications providing maximum versatility. The TXI8000 Series may be configured as a Single or Dual Channel Unit. The Dual Channel Unit consists of two PC Boards that are enclosed within the same housing and function independently of each other. This unit may be offered in any one of the seven standard input pressure signals or in any combination.

download datasheet

The T5400 Transducer is a digital-pneumatic device that provides a pneumatic output signal controlled by 8 bit digital data instructions from a central control room, a remote control location, or a local control station. This device is made up of two sections, the Signal Conversion Section and the Pneumatic Section. The Signal Conversion Section (PC Board) accepts an 8 bit parallel wired digital signal. Full scale output is divided into 255 parts and the output level is based on the logic state (high or low) of the 8 bits.

download datasheet

The T5420 is a Digital-Pneumatic Transducer, compatible with most digital systems using TTL and CMOS Logic. Its Fail safe High or Low will return the field reversible output to 3 psig for Direct Acting Mode or to 15 psig for Reverse Acting Mode if the power is lost, regardless of the logic selected. The Integral Volume Booster Output of the T5420 provides a flow capacity of 45 SCFM (76.5 m3/HR), to meet input requirements of final control elements requiring a higher capability output signal, increased output pressure, and/or increased flows.

download datasheet

The Fairchild Model 64 service regulator is a general purpose regulator (does not have a filter). The Model 64 service regulator has wider port to port mounting dimensions (3.15", 80 mm) making it the choice for field replacement of older style Fairchild and competitive service regulators that have wider mounting port spacing. The Model 64 pneumatic regulator is similarly well suited to general purpose service regulator applications as it has the highest flow capacity of any regulator in its class.

download datasheet

The Fairchild Model 2800 features control sensitivity of 0.5" water column to deliver consistent and reliable precision accuracy to maintain your desired set point regardless of system pressure changes or conditions. The Model 2800 pressure regulator will handle a 250 psi, 17 BAR maximum supply pressure and offers four (4) set point pressure ranges from 0.5-10 psi, 0.03-0.7 BAR, 3-70 kPa up to 2-150 psi, 0.15-10 BAR, 15-1000 kPa.

download datasheet

The Fairchild Model 3400 Lever Operated pressure Regulator is designed to allow rapid changes in pressure settings at control stations and test panels. This high quality unit, capable of handling high flows and exhausts combines positive control with good sensitivity. The Model 3400 Pneumatic Lever Operated Regulator is the combination of a Model 1000 High Flow Pressure Regulator and a hand held operated lever mechanism with 120 degree maximum travel.

download datasheet