Products of AQUAFINE

Aquafine Corporation was founded in 1949 by Louis Veloz, a Westinghouse scientist and pioneer in the development of commercial UV lamps for use in air and water purification. Introducing the use of UV technology in the semiconductor industry in the early 1960s, Aquafine continues to be the leader, expanding the product offering to meet the changing requirements of commercial water treatment.

In 2005, Aquafine became part of the Trojan Technologies group of Businesses. This combined entity is uniquely positioned to offer the marketplace with the best available technologies, conduct leading-edge research, develop innovative product offerings, and offer the highest quality in customer support.-

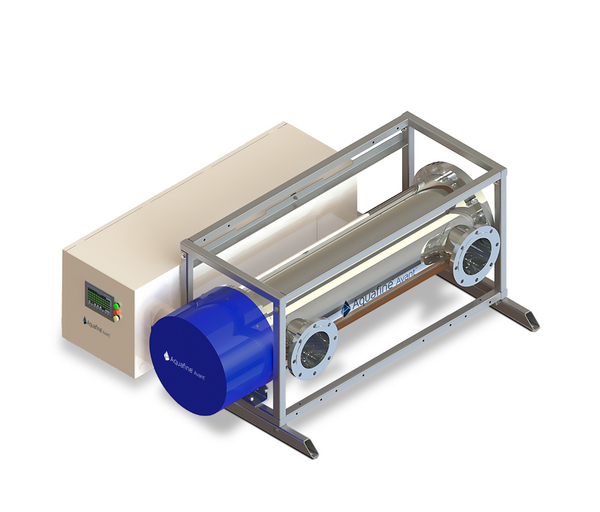

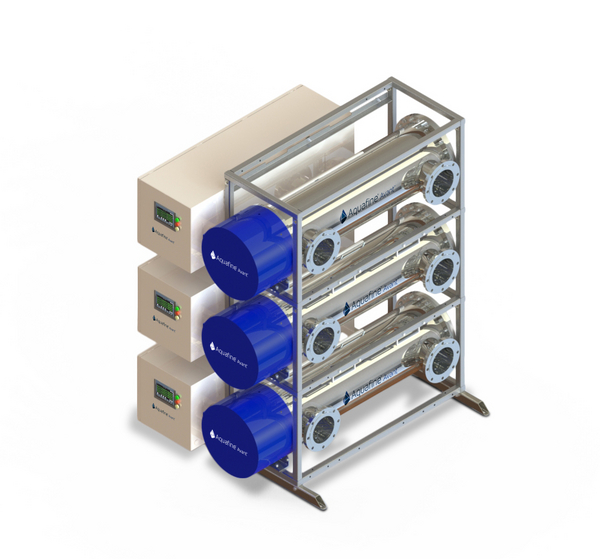

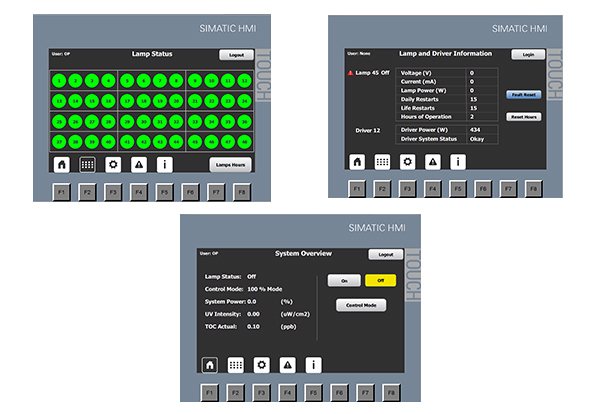

AVANT SERIES

Advanced TOC Destruction System for Ultra-Pure Water (UPW) Applications.

Avant Series is a state-of-the-art product that provides TOC reduction performance in up to a three times smaller footprint than prior series. The Avant series utilizes less energy and provides full flexibility for skid-mounted designs, with the ability to mount eight reactors in up to a 75% smaller footprint.

With the Predictive Maintenance capabilities, Avant ensures the system operates optimally and monitors the lamp characteristics of individual lamps and alerts the Plant Operators to change a lamp before failure, reducing unplanned maintenance costs and downtime.

Avant incorporates innovations, and best in-class components, to reduce the total cost of ownership and drastically simplify operation and maintenance. It is the ideal solution for Ultra-Pure Water (UPW) plants in need of revolutionary UV technology.-

Product Brochure

OPTIVENN SERIES

State-of-the-Art UV Series for Disinfection, TOC Reduction and Ozone Destruction.

The OptiVenn Series is a family of robust and flexible UV Systems with advanced technology designed to meet the stringent requirements of Pharmaceutical, Food & Beverage, Microelectronics and other Industrial Markets. The series consists of 316L stainless steel treatment chamber and 304 stainless steel control panel, with rating options for different environments. The OptiVenn Series is equipped with a Universal Controller which provides control, monitoring and operational information in a single convenient location. The treatment chamber and control panel are extremely compact, yet offer flexibility of installation to accommodate into different skid designs or as a stand-alone UV System.-

Product Brochure

SWIFTBEVERAGE SERIES

Designed as a cost-effective, high performance system for maximum water confidence.

The SwiftBeverage Series offers validated UV for beverage disinfection that exceeds FDA and USEPA compliance requirements. This proven protection safeguards against virtually all microorganisms, including Cryptosporidium, Giardia and Adenovirus, proving greater safety and peace of mind.Aquafine SwiftBeverage systems additionally comply with the Pasteurized Milk Ordinance (PMO) for the dairy industry and have been designed to meet the diversion requirement, to regulate flow and to have the required sensor per lamp to ensure full compliance with the PMO. Aquafine works closely with the PMO specification organization and has supplied numerous PMO compliant units.Featuring the industry’s most advanced low-pressure, high-output (LPHO) amalgam lamp technology, the SwiftBeverage series consists of a 316L stainless steel treatment chamber and a NEMA-3R stainless steel control cabinet featuring a microprocessor-based controller. The compact size maximizes installation flexibility and preserves floor space with the ability to mount in line, horizontally or vertically and complies with stringent NSF 61 standard.-

Product Brochure

CHLORID SERIES

High Performance UV Treatment System - Low footprint UV disinfection system for the reduction of chlorine and chloramines using medium-pressure lamp technology.

Utilizing medium-pressure lamp technology, our ChloRid series for chlorine reduction is the system of choice for meeting the rigid quality standards of the Life Sciences and Food & Beverage markets Consisting of a 316L stainless steel treatment chamber and a UL Type 3R stainless steel control cabinet, the ChloRid series features a microprocessor-based controller and optional sanitary fittings and wiper. The incorporation of MP high intensity ultraviolet (UV) lamps reduces the number of lamps by 90 percent, reducing footprint, downtime requirements and installation and maintenance costs. With a reduced footprint, higher flow rates and state-of-the-art MP technology, Aquafine Corporation’s ChloRid systems are an innovative, reliable and environmentally responsible alternative. ChloRid systems are cULus listed and CE pending.-

Product Brochure

AQUAFINE LOGIC SERIES

A robust, highly versatile and cost effective UV water treatment system featuring proven low pressure, high-output amalgam lamp technology.

System of choice for meeting the rigid quality standards of the Recreational Water, Life Sciences and Food & Beverage markets. Featuring the industry’s most advanced low-pressure, high-output (LPHO) amalgam lamp technology - the TrojanUVLogic Series consists of a 316L stainless steel treatment chamber and a UL TYPE-3R 304 stainless steel control cabinet featuring a microprocessor-based controller. The L-shaped reactor design was developed using advanced computer modeling, resulting in 40% greater hydraulic efficiency than conventional systems.

The compact size maximizes installation flexibility and preserves floor space with the ability to mount in line, horizontally or vertically. Single-ended lamps and quartz sleeves allow fast lamp change-outs without tools, and features an optional manual or automated sleeve cleaning system that can be operated while the reactor is online. In addition to a comprehensive list of standard features, each system undergoes rigorous quality checks and electronic functionality and hydrostatic pressure testing before leaving our facility.-

Product Brochure

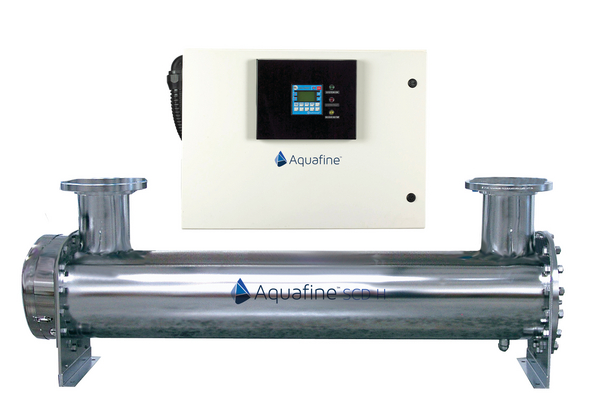

SCD H SERIES

Provides TOC and chlorine destruction solutions for high volume, ultrapure, waste or reclaim applications.

Aquafine SCD H systems for TOC (total organic carbon) and chlorine destruction can be found worldwide in state-of-the-art microelectronic facilities and life science applications - where meeting stringent criteria of the cGMP and full acceptance by the FDA are mandatory.

Perfect for ultrapure, waste or reclaim applications, the unit’s compact size reduces footprint and maximizes installation flexibility, which is suitable for indoor or outdoor installations. Single-ended (SE) HX lamps allow quick change-outs without tools.

The SCD H series consists of 316L stainless steel treatment chamber and a UL TYPE-1 painted carbon steel control cabinet, with a maximum cable length of 15 ft. (5m). The control cabinet features a microprocessor-based controller.-

Product Brochure

SL SERIES

Provides a compact design and economical ultraviolet (UV) water treatment for lowflow disinfection applications.

These compact and economical units are used for low-flow applications such as laboratory and medical facility water, life sciences pharmaceutical make-up process, final electronic component rinsing and recirculation loops.

The SL-1 and MP-2-SL models can be configured for TOC reduction or ozone destruction applications. The Aquafine Corporation SL Series consists of a 316L stainless steel treatment chamber and a 304 stainless steel control panel in one integral unit. All units come complete with a standard Running Time Meter.-

Product Brochure

MPR SERIES

Our MPR systems meet and exceed the diverse needs of market-specific applications for disinfection and chloramines reduction.

The MPR series consists of 316L stainless steel, matte finish treatment chamber and a UL Type 12 painted carbon steel control cabinet, featuring a microprocessor-based controller an optional automatic wiper. The incorporation of MP high intensity ultraviolet (UV) lamps reduces the number of lamps by 90%, reducing footprint, downtime requirements, installation and maintenance costs. All systems in the series are CE compliant, as well as cULus and NSF 50 certified.-

FLOWRATES: 786-2,895gpm @ 95%UVT

Product Brochure

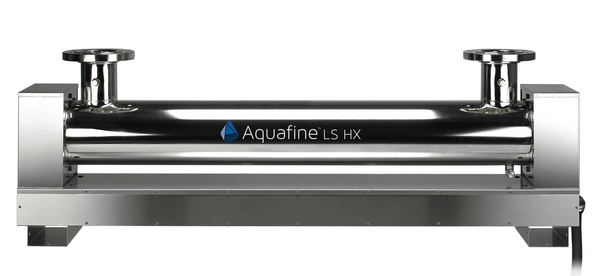

LS HX SERIES

Our LS HX systems can significantly reduce microbial counts by destroying at least 99.9% of the bacteria present in the influent syrup stream.

The LS HX Series provides maximized disinfection of syrups, including simple syrups, syrup mixes and high-fructose corn syrups using low-pressure, high-output lamp (LPHO) technology. The LS HX series consists of a 316L stainless steel treatment chamber with sanitary connections and a standard stainless steel control cabinet, with a maximum cable length of 15 ft. (5m). The control cabinet features the UV & Temperature Monitoring System for 12 lamp models or UVG400 controller for 24 and 36 lamp models. The HX lamp provides increased process performance and extended lamp life, while the system’s compact size allows for a smaller footprint, maximizing installations flexibility. Single-ended (SE) HX lamps allow quick change-outs without tools.

FLOWRATES: 25-150gpm @ 55%UVT

Product Brochure